Ceramic foam filter

Description:

Alumina ceramic foam filters are mainly used for filtering aluminum and aluminum alloys in foundries . Alumina ceramic foam filter has excellent resistance to corrosion and corrosion of molten aluminum, to effectively remove large impurities in the aluminum liquid and absorb micro-level fine impurity particles, reduce residual gas and provide laminar flow, and then make the filtered metal Obviously more transparent. Cleaner metals can produce higher quality castings, less scrap and fewer inclusion defects, all of which help increase profits.

It is widely used in the production of aluminum profiles, aluminum foil and aluminum alloys.

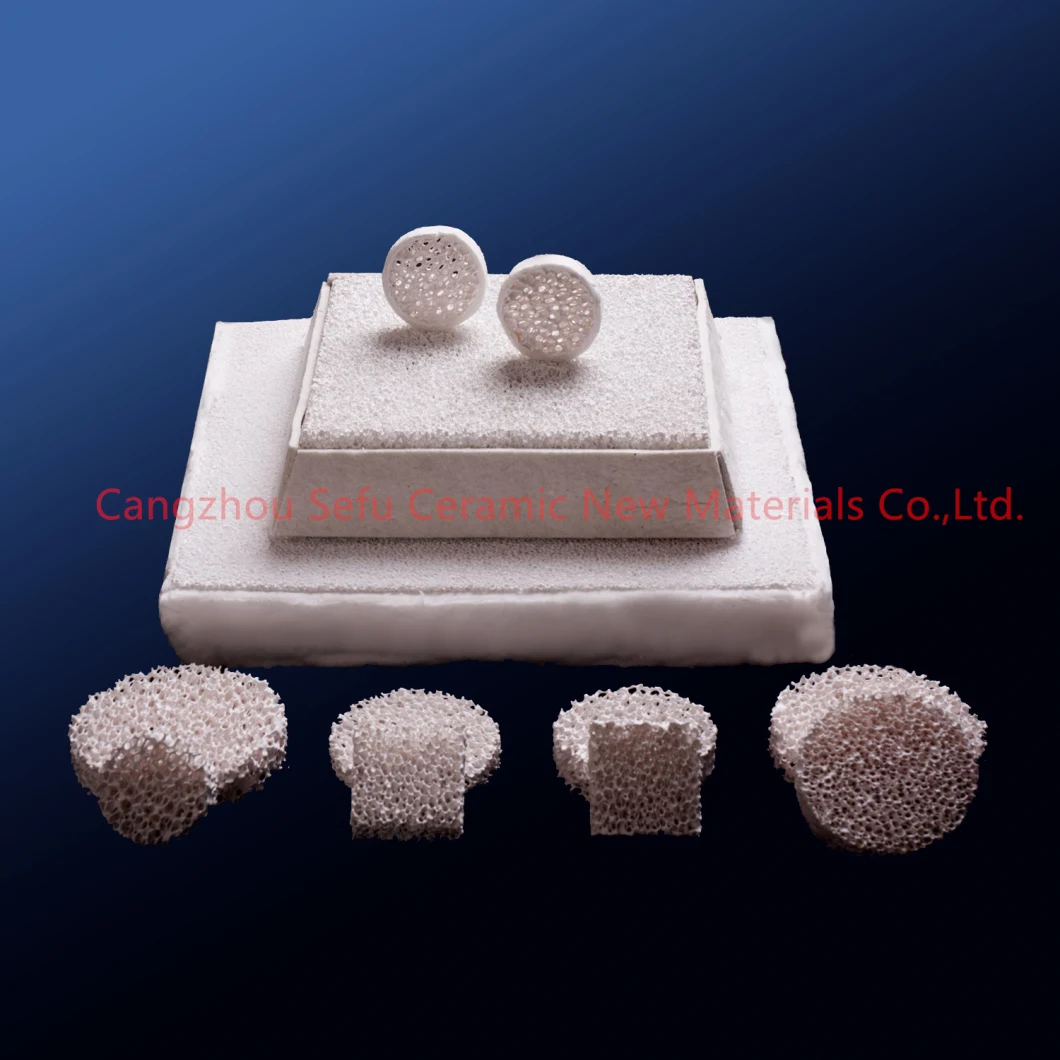

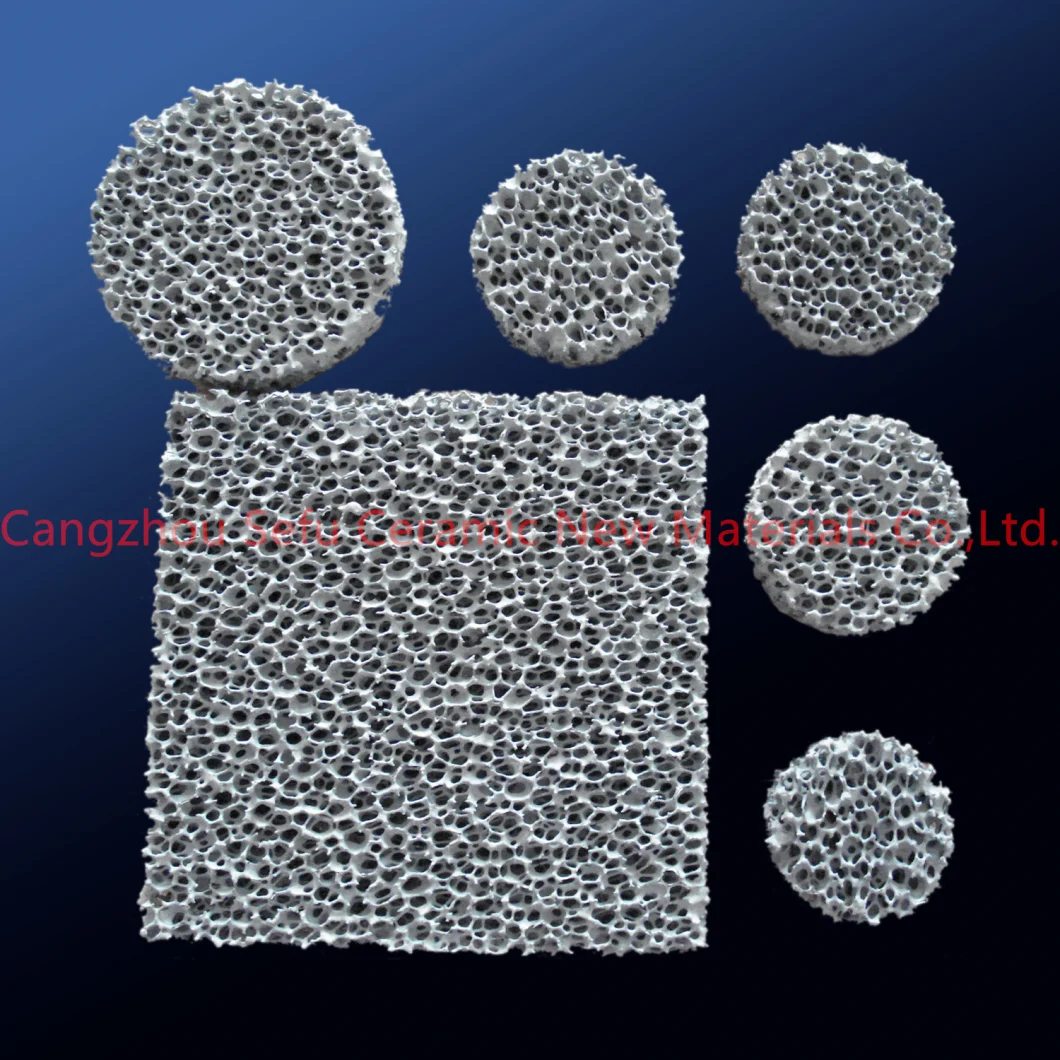

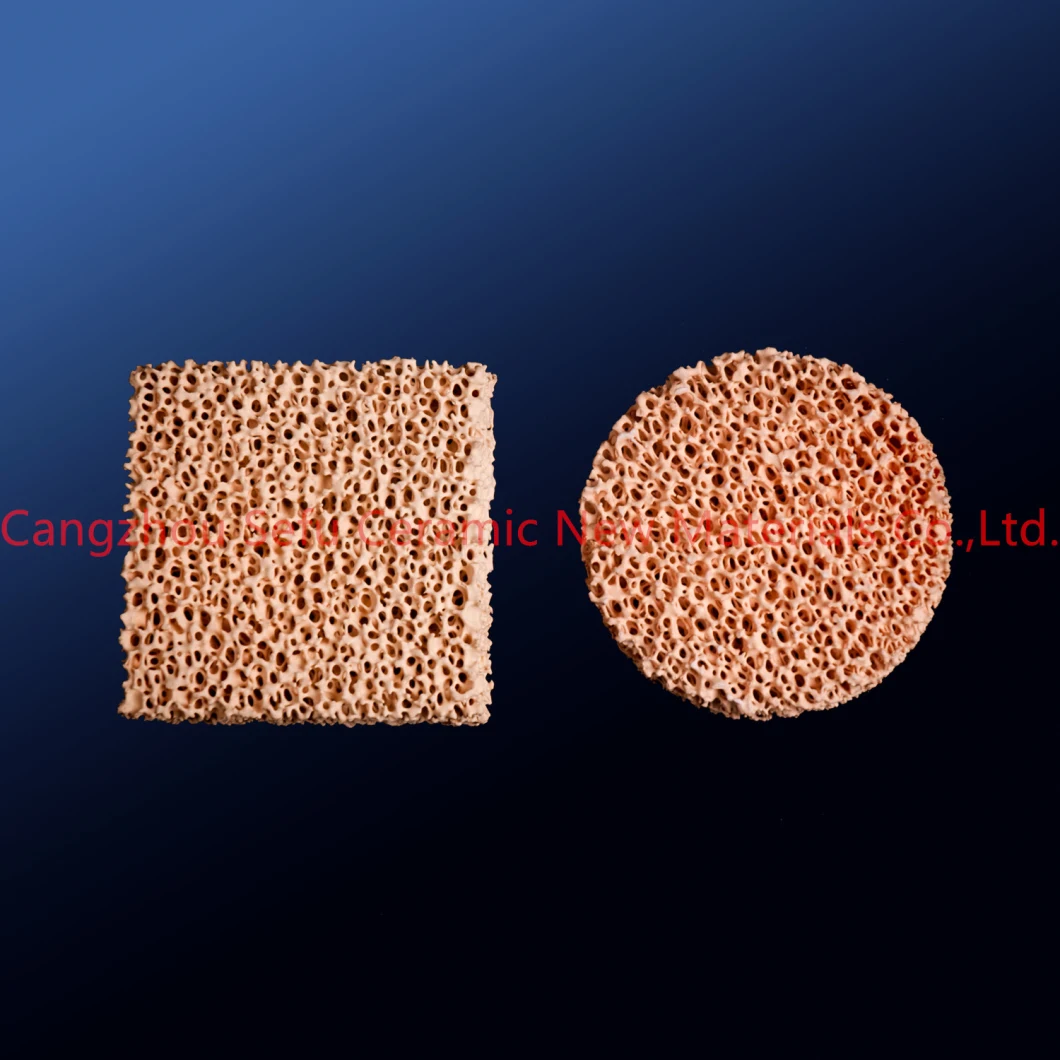

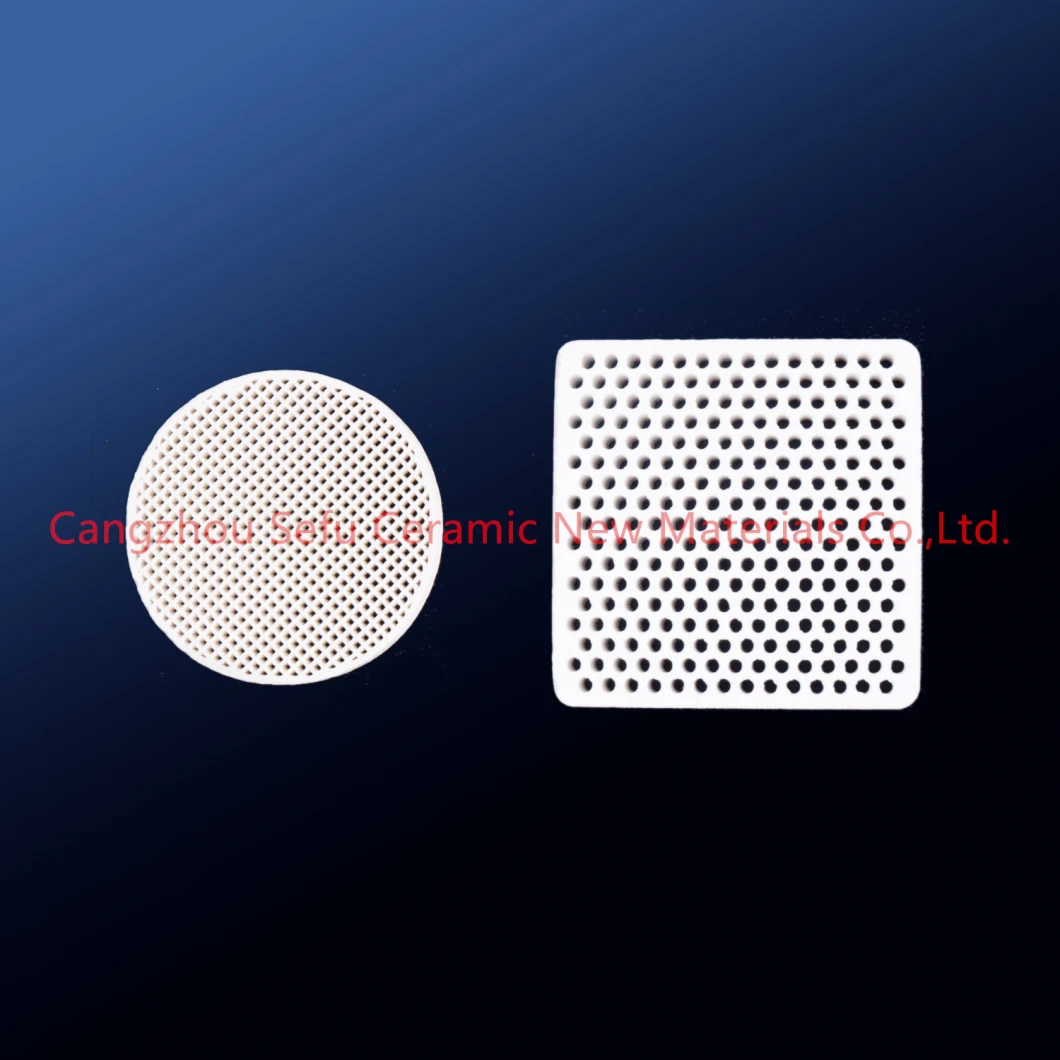

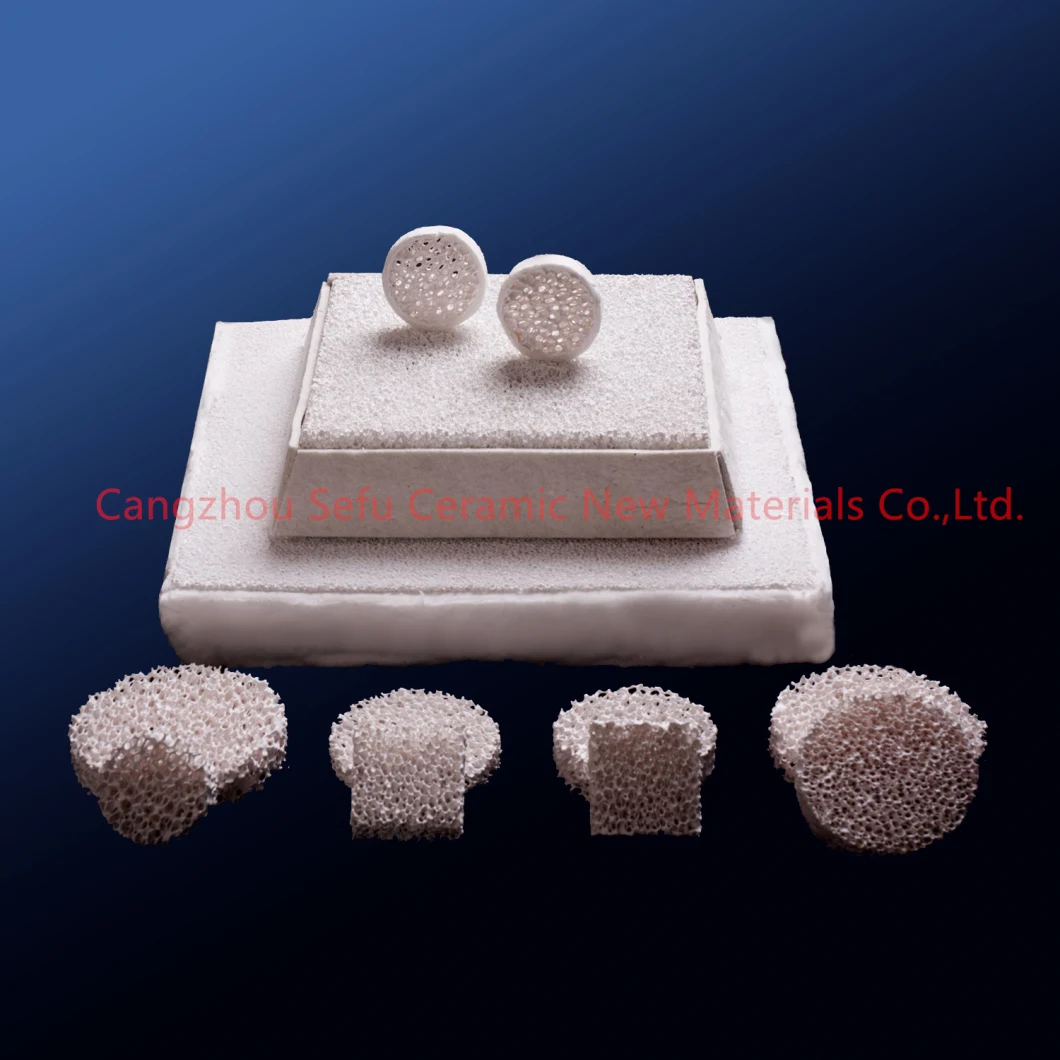

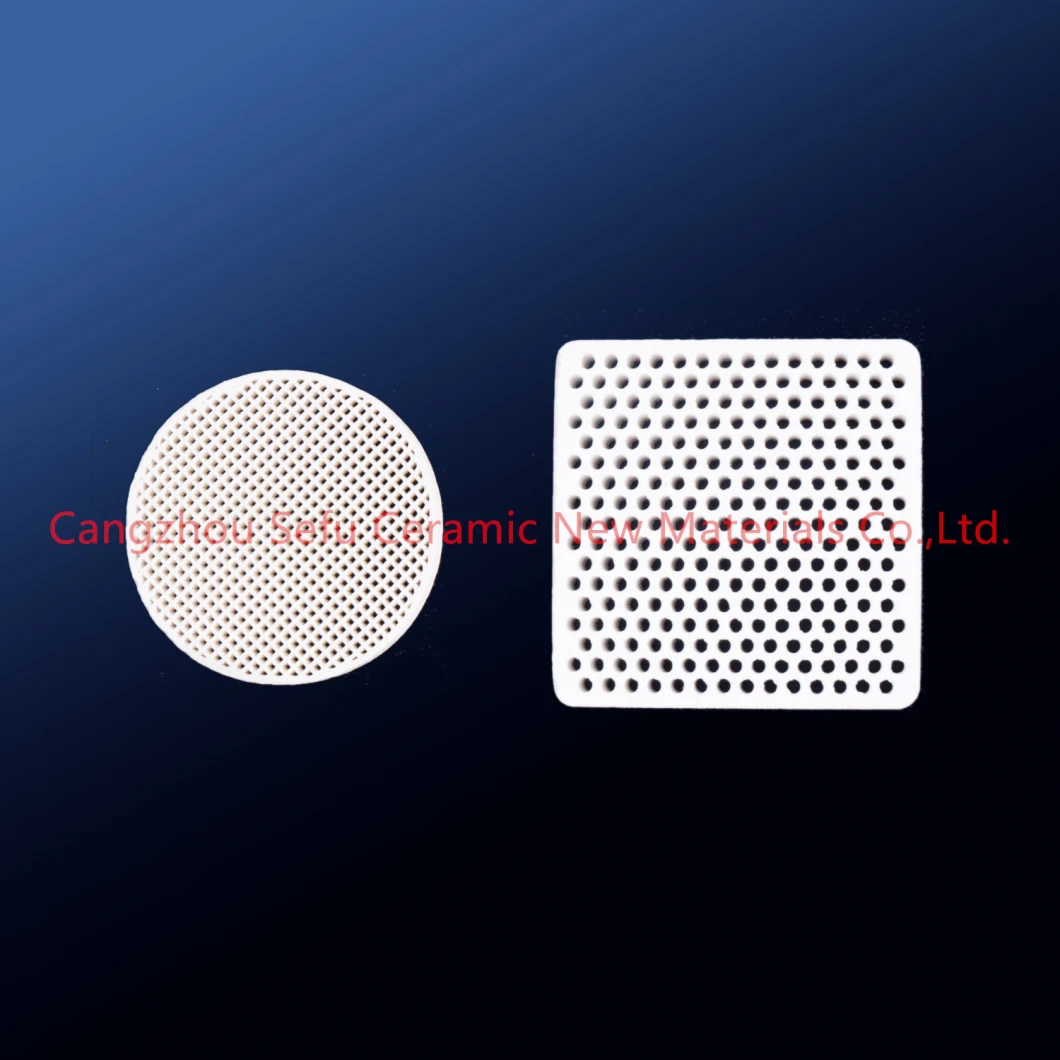

The size are available in square, round and custom geometric shapes; sizes ranging from 10mm up to 600mm, and thicknesses from 10-50mm.

The production process and principle of the filter

Manufacturing porous alumina ceramic foam filters, using a three-dimensional network structure and organic foam sponge connected to the pores as a carrier, invading it into a special ceramic slurry with thixotropy, and uniformly coated by a special roll extrusion process The skeleton of the ceramic paste to the carrier.

Then, it is dried and cured, and then fired at high temperature to complete. All our processes are under the supervision of ISO9001 quality system certificate. Each test is self-checked by a full-time inspector. In order to ensure the quality of the filter, appearance and strength tests must be performed. Porous ceramic foam filter Aluminum alloy foam ceramic filter Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

Advantages of Alumina ceramic foam filters

High strength, no loose ceramic particles or powder

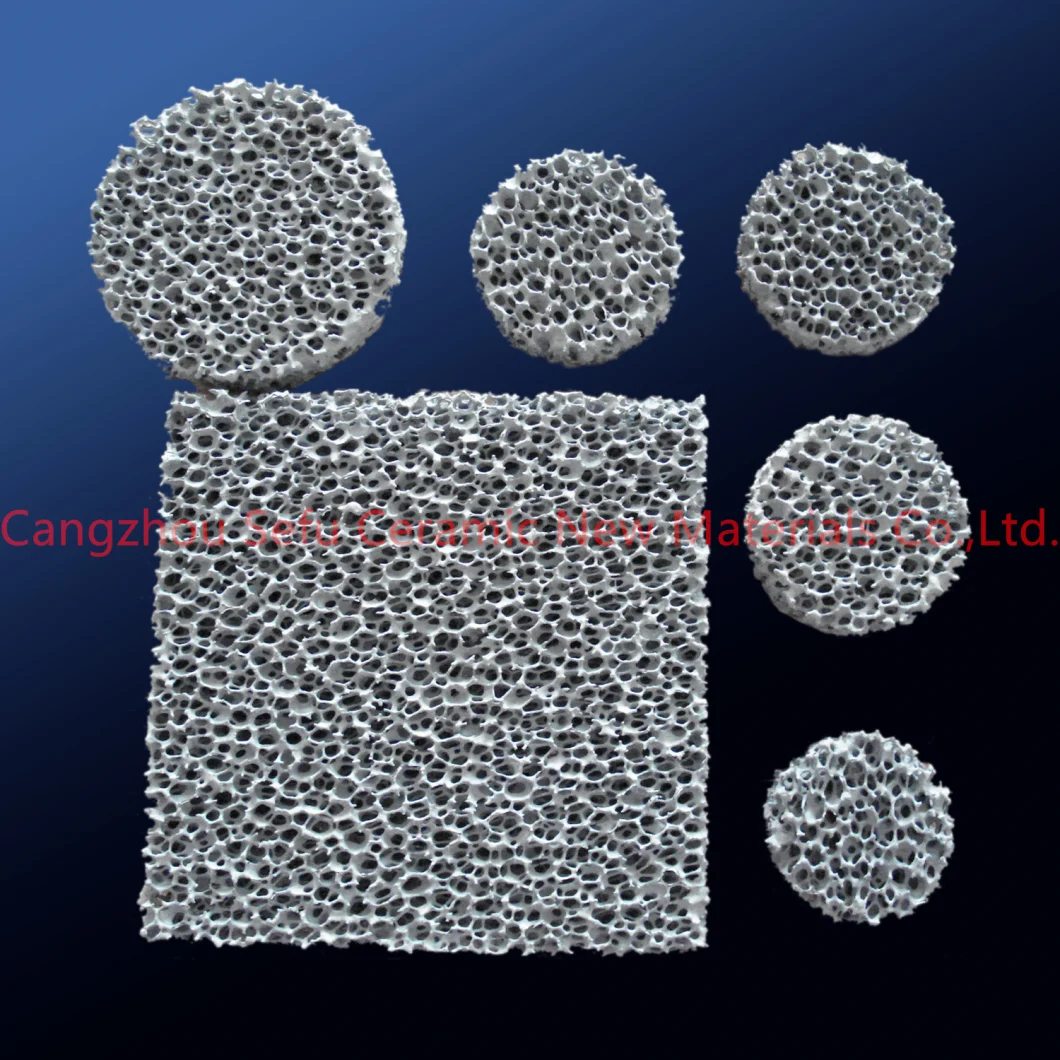

Three-dimensional connected mesh structure, high porosity

Large surface area for slag collection and large surface area for filtration

Excellent thermal shock resistance

Particles larger than the pore size are captured on top of the ceramic foam filter

Smaller particles are trapped on the filter cake by larger particles

Fine particles are trapped in the pores of the filter

Specification of Ceramic Foam Filters

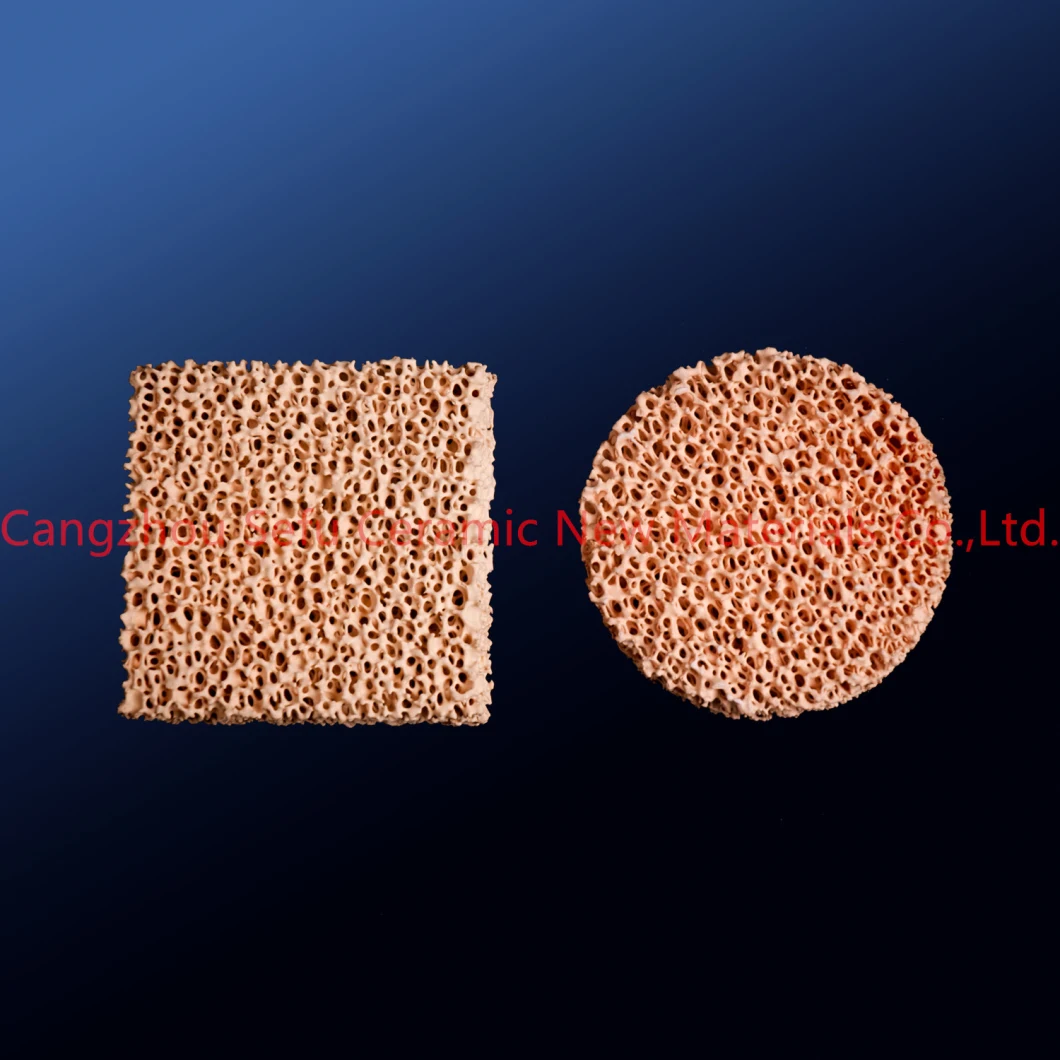

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceramic New Materials Co.,Ltd.

Description:

Alumina ceramic foam filters are mainly used for filtering aluminum and aluminum alloys in foundries . Alumina ceramic foam filter has excellent resistance to corrosion and corrosion of molten aluminum, to effectively remove large impurities in the aluminum liquid and absorb micro-level fine impurity particles, reduce residual gas and provide laminar flow, and then make the filtered metal Obviously more transparent. Cleaner metals can produce higher quality castings, less scrap and fewer inclusion defects, all of which help increase profits.

It is widely used in the production of aluminum profiles, aluminum foil and aluminum alloys.

The size are available in square, round and custom geometric shapes; sizes ranging from 10mm up to 600mm, and thicknesses from 10-50mm.

The production process and principle of the filter

Manufacturing porous alumina ceramic foam filters, using a three-dimensional network structure and organic foam sponge connected to the pores as a carrier, invading it into a special ceramic slurry with thixotropy, and uniformly coated by a special roll extrusion process The skeleton of the ceramic paste to the carrier.

Then, it is dried and cured, and then fired at high temperature to complete. All our processes are under the supervision of ISO9001 quality system certificate. Each test is self-checked by a full-time inspector. In order to ensure the quality of the filter, appearance and strength tests must be performed. Porous ceramic foam filter Aluminum alloy foam ceramic filter Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

Advantages of Alumina ceramic foam filters

High strength, no loose ceramic particles or powder

Three-dimensional connected mesh structure, high porosity

Large surface area for slag collection and large surface area for filtration

Excellent thermal shock resistance

Particles larger than the pore size are captured on top of the ceramic foam filter

Smaller particles are trapped on the filter cake by larger particles

Fine particles are trapped in the pores of the filter

Specification of Ceramic Foam Filters

| Specification(inch) | Filter Size(mm) | Remark |

| 7 inches | 178*178*50 | 1.10-30ppi continuous casting and rolling of aluminum alloy bars 2.30-50ppi semi-continuous casting 3.40-50ppi for high-quality aluminum profiles and plates 4.50-60ppi for double zero wave continuous casting and rolling |

| 9 inches | 228*228*50 | |

| 12 inches | 305*305*50 | |

| 15 inches | 381*381*50 | |

| 17 inches | 432*432*50 | |

| 20 inches | 508*508*50 | |

| 23 inches | 584*584*50 | |

| 26 inches | 660*660*50 |

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

- Inside packing: Filters are put in small box and Layered packaging. There is cardboard between each layer.

- Outside packing: Cartons&Pallets. Three layer corrugated cartons and export special pallets .

- The mark on cartons can be designed according to the customer's request.

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceramic New Materials Co.,Ltd.