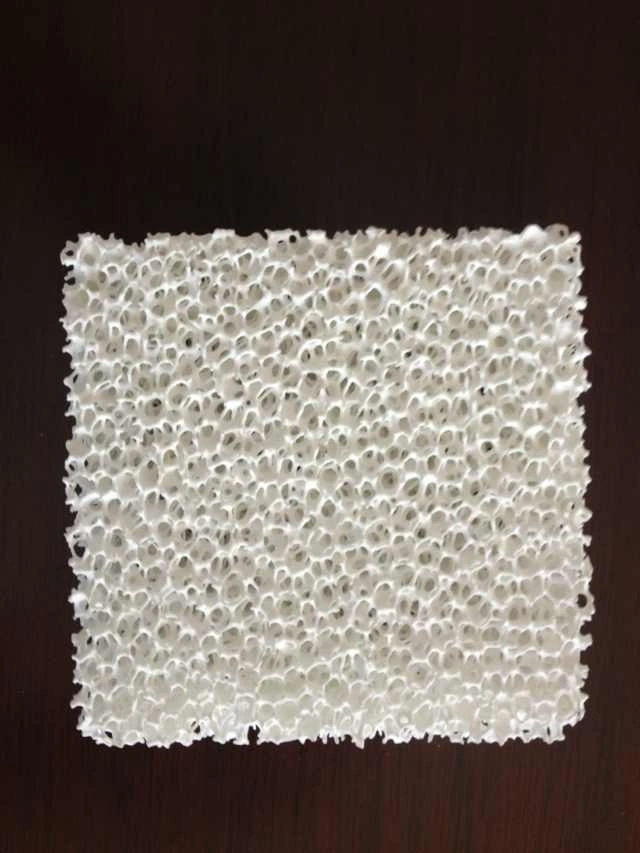

Ceramic Foam Filter Description:

Ceramic Foam Filter is a porous material with a high-temperature properties. Its diameter from the nanometer to the micron range, porosity is from 20% to 95%, and the use of a temperature can reach up to 1600° C.

Specifications

1. Usable at high temperature, high strength

2. Erosion resistance, minimal volume change

3. Effectively filter out impurities

Production process

*three-dimensional network structure and connected pores organic foam

*using four correction center distance and automatic extrusion

*1320 ° C Drying and solidification

Application

*effectively remove and absorb impurities

*improve the surface quality, product performance and microstructure effectiveness.

*mainly used in the domestic, construction, electricity, condensing tubes, cable and other aluminum alloy precision casting.

Usage process

*Clean the aluminum filter box, keep it clean and intact

*Put the ceramic foam filter into filter box carefully, press Sealing gasket around, avoid molten aluminum Dispersing orfloating away.

*Preheat filter box and ceramic foam filter evenly 15-30min, preheating temperature should surpass 460° C. Expansion cotton will seal after heating

*Observe change of molten aluminum pressure, control the flowing molten aluminum needed, normal start pressure: 100-150mm. The pressure falls down bellow 75-100mm when molten aluminum flowing, it will grow later.

*Do not shock and beat ceramic foam filter in filtration. Control molten aluminum flow rate in launder.

*Take out ceramic foam filter and clean filter box after filtration.

Merits:

*Easily installed

*Resistant to molten aluminum

*Non-wetting

*Excellent hot strength

*Dimensionally stable

*Suitable for both horizontal and vertical placement

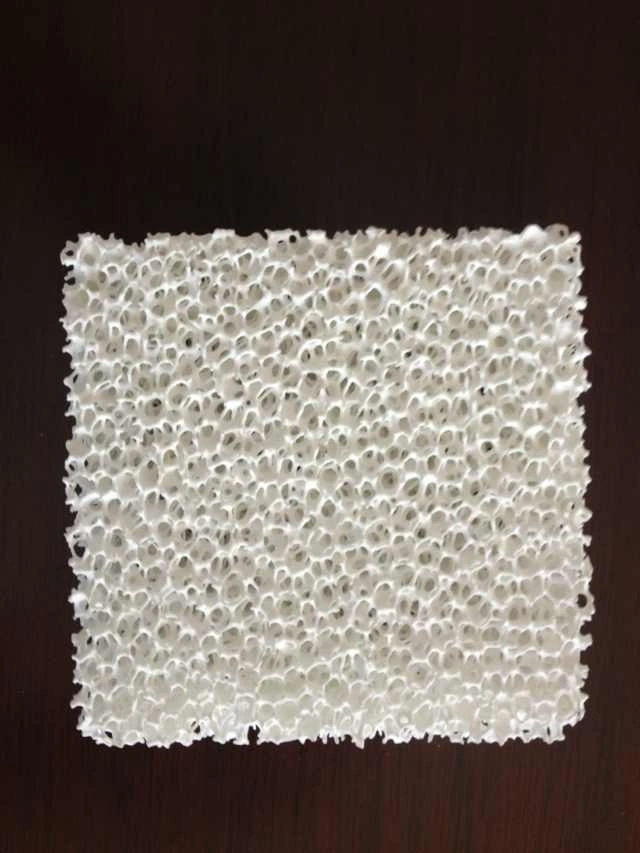

Ceramic Foam Filter is a porous material with a high-temperature properties. Its diameter from the nanometer to the micron range, porosity is from 20% to 95%, and the use of a temperature can reach up to 1600° C.

Specifications

1. Usable at high temperature, high strength

2. Erosion resistance, minimal volume change

3. Effectively filter out impurities

Production process

*three-dimensional network structure and connected pores organic foam

*using four correction center distance and automatic extrusion

*1320 ° C Drying and solidification

Application

*effectively remove and absorb impurities

*improve the surface quality, product performance and microstructure effectiveness.

*mainly used in the domestic, construction, electricity, condensing tubes, cable and other aluminum alloy precision casting.

Usage process

*Clean the aluminum filter box, keep it clean and intact

*Put the ceramic foam filter into filter box carefully, press Sealing gasket around, avoid molten aluminum Dispersing orfloating away.

*Preheat filter box and ceramic foam filter evenly 15-30min, preheating temperature should surpass 460° C. Expansion cotton will seal after heating

*Observe change of molten aluminum pressure, control the flowing molten aluminum needed, normal start pressure: 100-150mm. The pressure falls down bellow 75-100mm when molten aluminum flowing, it will grow later.

*Do not shock and beat ceramic foam filter in filtration. Control molten aluminum flow rate in launder.

*Take out ceramic foam filter and clean filter box after filtration.

Merits:

*Easily installed

*Resistant to molten aluminum

*Non-wetting

*Excellent hot strength

*Dimensionally stable

*Suitable for both horizontal and vertical placement

| Chemical composition | Al 2 O 3 | Fe 2 O 3 | SiO 2 | others |

| model index(%) | 89.6 | 0.24 | 2.42 | 7.5 |

| dimensions(mm) | filtration area(%) | filtration range(kg/min) |

| 7in(178*178*50) | 68 | 22-42 |

| 9in(229*229*50) | 70 | 42-68 |

| 12in(305*305*50) | 73 | 60-135 |

| 15in(381*381*50) | 79 | 90-240 |

| 17in(432*432*50) | 80 | 125-310 |

| 20in(508*508*50) | 82 | 170-420 |

| 23in(584*584*50) | 84 | 230-580 |