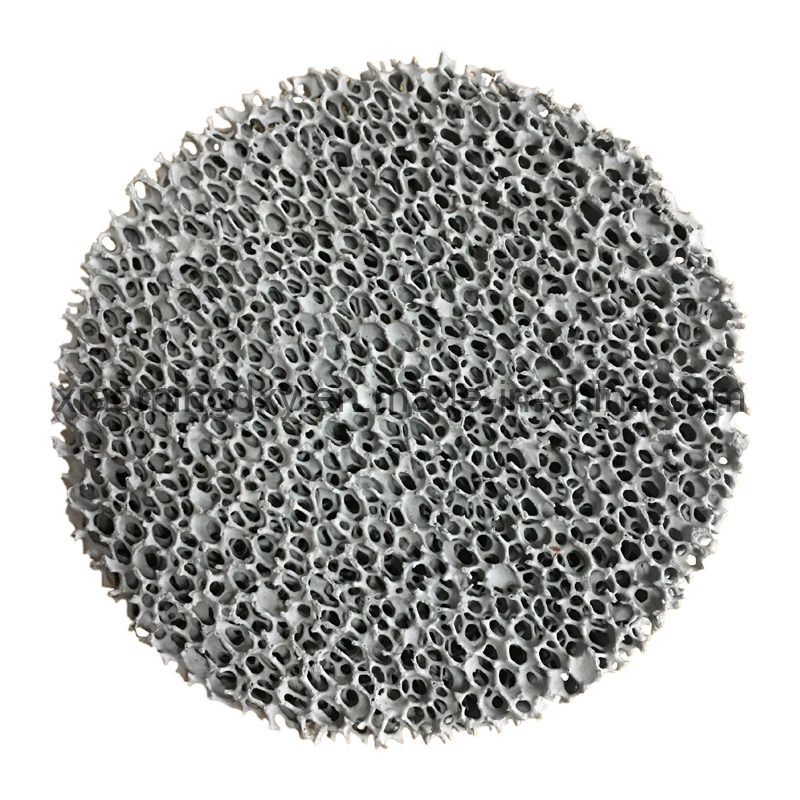

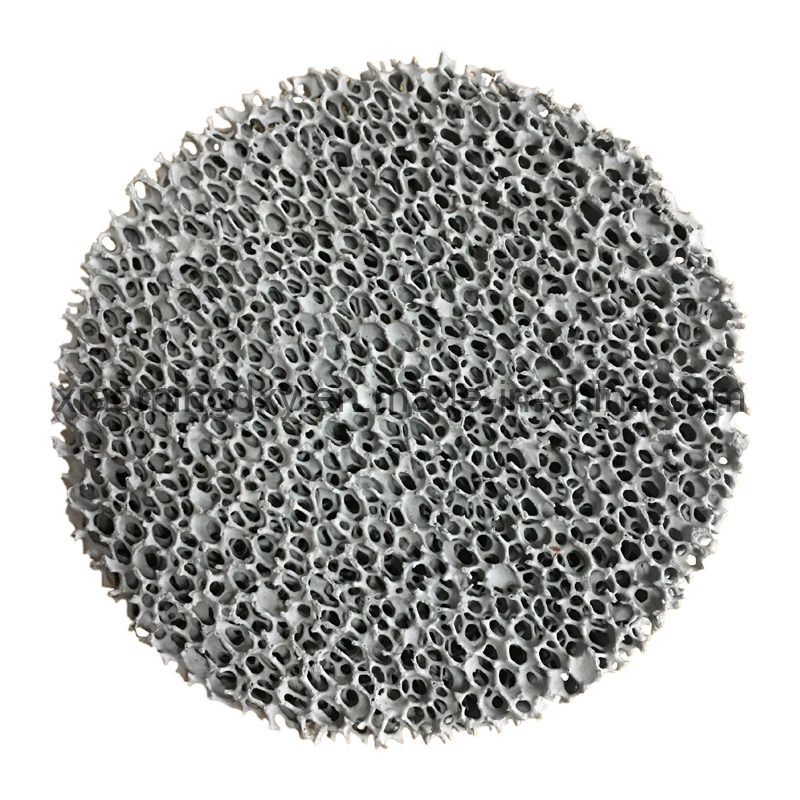

SIC Ceramic Foam filters are just developed as a new type molten metal filter to decrease casting flaw in recent years. With its characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, erode resistance, high-performance, SIC Ceramic Foam filter is designed for filtering impurities from molten Iron & Alloy, nodular cast iron castings, grey iron castings and malleable castings, Bronze casting, etc. With their excellent resistance to attack and corrosion from molten iron liquid, SIC Ceramic Foam filter can effectively remove inclusions, reduce trapped gas from liquid metal and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Functions:

*Decontaminate the melting metal liquid

*Simplified gating system

*Improve the metallurgical structure of the castings

*Reduce slag inclusions of the castings

*Improve the casting quality rate

*Reduce casting internal re-oxidation defects

*Reduce the surface defects after machining of the castings

Advantages:

*Filter the surdries in the castings, reduce the casting splracles, reduce the veins flowing when pouring the casting, reduce surface defects, obviously to improve the final-product rate

*Reduce castings manufacturing duration and the sword and tool damages, improve casting surface manufacturing quality

*Strengthen castings anti-pressure and airproof features, strengthen elongate anti-resistance intensity, to improve surface glabrousness

*Predigest casting system designing requirement, reduce the length of horizontal casting channel, improve castings technology output rate

Functions:

*Decontaminate the melting metal liquid

*Simplified gating system

*Improve the metallurgical structure of the castings

*Reduce slag inclusions of the castings

*Improve the casting quality rate

*Reduce casting internal re-oxidation defects

*Reduce the surface defects after machining of the castings

Advantages:

*Filter the surdries in the castings, reduce the casting splracles, reduce the veins flowing when pouring the casting, reduce surface defects, obviously to improve the final-product rate

*Reduce castings manufacturing duration and the sword and tool damages, improve casting surface manufacturing quality

*Strengthen castings anti-pressure and airproof features, strengthen elongate anti-resistance intensity, to improve surface glabrousness

*Predigest casting system designing requirement, reduce the length of horizontal casting channel, improve castings technology output rate

| Material | Silicon Carbide | |

| Applied Temp. ( ° C) | ≤ 1500 | |

| Color | Grey-Black | |

| Pore Size ( PPI ) | 10/15/20/30/40 | |

| Porosity ( % ) | 80 ~ 90 | |

| Compressive Strength ( MPa ) | ≥ 1.0 | |

| Bulk Density ( g/cm3 ) | 0.4 ~ 0.6 | |

| Thermal Shock Resistance | Excellent | |

| Composite | Al 2 O 3 (%) | 15 ~ 25 |

| SiO 2 (%) | 10 ~ 25 | |

| SiC(%) | 55 ~ 65 | |

| Others(%) | 0 ~ 5 | |

| Specification ( mm ) L.W.T | 10 ppi | 20 ppi | ||||||

| Pouring Capacity ( kg ) | Pouring Rate ( Kg/sec ) | Pouring Capacity ( kg ) | Pouring Rate ( Kg/sec ) | |||||

| Grey iron | Ductile | Grey iron | Ductile | Grey iron | Ductile | Grey iron | Ductile | |

| 40 × 40 × 22 | 80 | 40 | 5 | 3 | 64 | 32 | 4.5 | 2.5 |

| 50 × 50 × 22 | 100 | 50 | 6 | 4 | 80 | 40 | 5 | 3 |

| 75 × 50 × 22 | 150 | 75 | 9 | 6 | 120 | 60 | 7 | 5 |

| 100 × 50 × 22 | 200 | 100 | 12 | 8 | 160 | 80 | 10 | 6.5 |

| 75 × 75 × 22 | 220 | 110 | 14 | 9 | 176 | 88 | 11 | 7 |

| 100 × 75 × 22 | 300 | 150 | 18 | 12 | 240 | 120 | 14 | 9 |

| 100 × 100 × 22 | 400 | 200 | 24 | 16 | 336 | 168 | 20 | 13 |

| 150 × 150 × 25 | 900 | 450 | 54 | 36 | 720 | 360 | 40 | 30 |