Product Description

The PVC foam board produced by our SJ65/132 extrusion line is a new type of environmentally friendly plastic material and a perfect substitute for wood and steel. Compared with wood, it has many advantages: light weight, good flexibility, flame retardant, alkali and acid resistance, moisture proof, waterproof, heat preservation, sound insulation, shock absorption, etc. The board can be photographed or printed in color. It has a variety of processing methods, such as nails, saws, planning, cementing, joining, etc.

feature:

1. Light weight, no water absorption, flame retardant and self-extinguishing

2. Sound insulation, heat insulation, sound absorption, heat preservation and corrosion protection.

3. Weatherproof, anti-vandalism, and can be shaped, molded, painted and screen printed.

4. No warpage and anti-fouling.

5. Non-corrosive, non-toxic and chemical resistant.

6. Tough, rigid, high impact strength.

7. Easy to clean and maintain.PVC eaves rain gutter making process

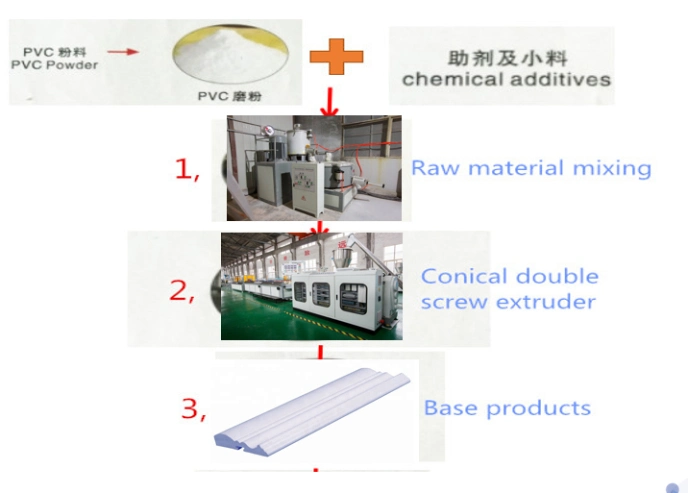

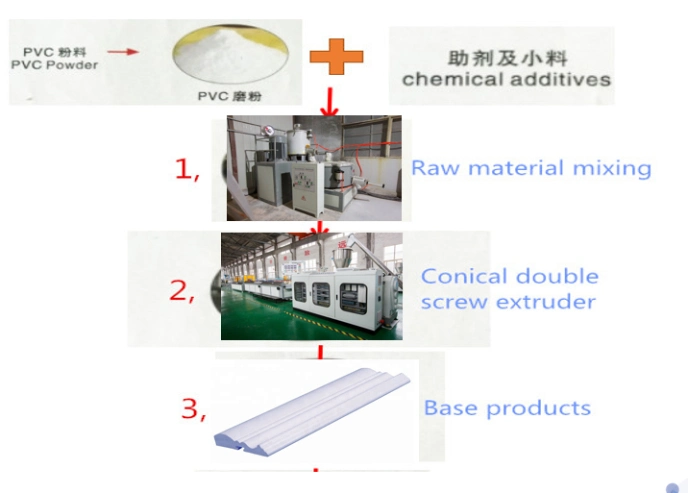

1,Raw material mixer

Function:Mixing all raw materials together by hot mixer and so then can compound well,then cooling by the cold mixer prevent reaction.

Working process:Automatic loading feeder--6-10min hot mixing--10-15min cooling

In order to avoid pollution, the mixer needs to be alone in a room. In addition, the mixed raw materials can be stored in silos, then transported directly from the silo to the extruder.

2,PVC eaves rain gutter extrusion line

Function and working process:

Automatic loading ----Conical double screw extruder ---die mould---calibrator platform cooling----haul off device---Automatic cutting machine---Productus stacker

Special design screw for PVC powder extrusion,SIEMENS brand motor,famous brand gear box,with automatic loading and feeder

In order to cooling the products well,adopt the cauum pump and water pump,two sets water tank.All parts contact with water are made by stainless steell.

The haul off device clamped the products by the rubber block, then the movement of the rubber block pulls the product forward.

Automatic cutting machine can customized cut the final products at the required length .

It has the functions of measuring cutting and accumulative counting.It adopt with the dust collector avoid pollution.

Carry and support the cutted final product, and then arrange neatly.

Made of stainless steel, the slide rail is equipped with a rubber protective layer.

3,PVC eaves rain gutter mould

We can design the mold according your requirments,mould material: 3cr17,the special high-quality mold steel

We offer the mold for 60 /65/80/85 series PVC window and doors,the co-extrusion type for ASA surface and sealing rubber.

4,SWP360 Plastic crusher

The crusher used to recycling the waste products ,then cutting them into small flakes.

5,SMW-500 high speed PVC Grinding machine

The high speed PVC grinding machine used to milling the PVC flakes into powder,so the waste PVC products can be recycled use.

6,20HP Water chiller :HANGKANG ANGES brand,Danfoss compressor

Cooling the recycle water which used to cooling the products,

so it can increace the production speed and get good products surface.

7,30A air compressor

Provide the air to the mold,cylinder for haul off device,cutter,and stacker

Plastic PVC foamed profiles making machine details

PVC foamed profile making machine model

1,Main extruder2,Mold for PVC eaves rain gutter 3,Cooling and calibranting machine4,Haul off machine 5,Cutting machineFeatures and application for PVC foamed profiles

Features compared with wood and WPC

Application for PVC foamed profiles

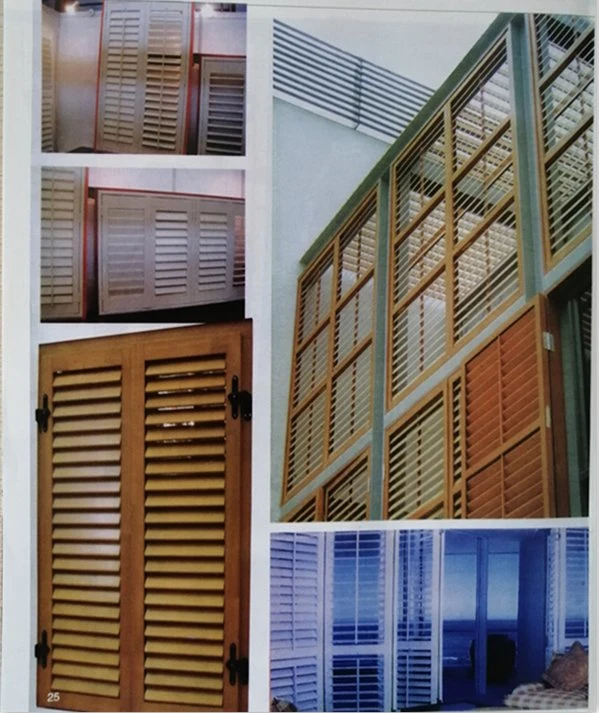

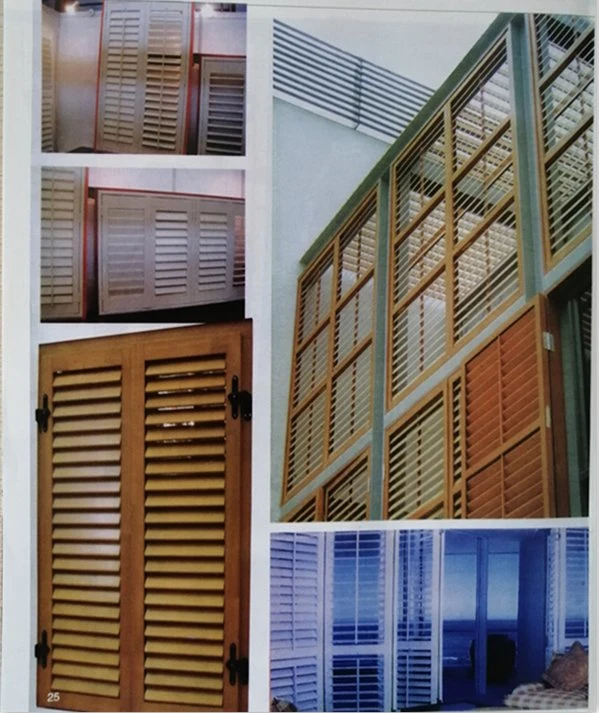

1.PVC foamed chamfer strip is a triangular strip of rigid PVC or Foam PVC, nailed to concrete formwork in various places: outside corners, around window or door openings, at the top of an exposed wall, etc.

2.Fireproof, waterproof, antiseptic, no broken by nailing, no broken by Curving, replacing Wood

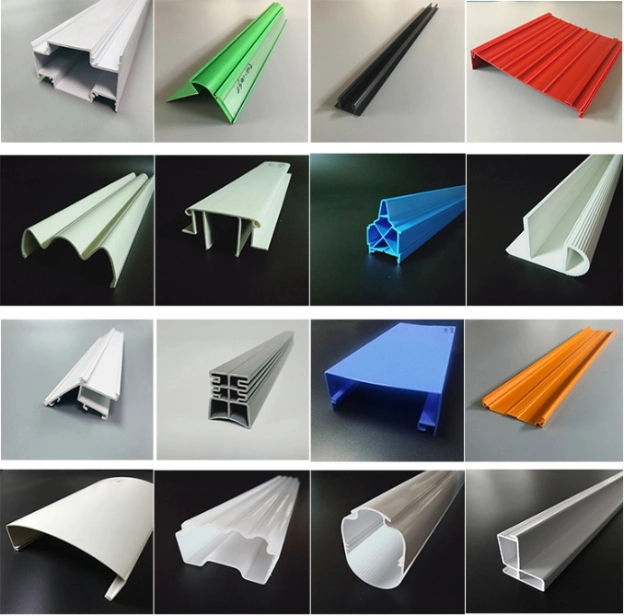

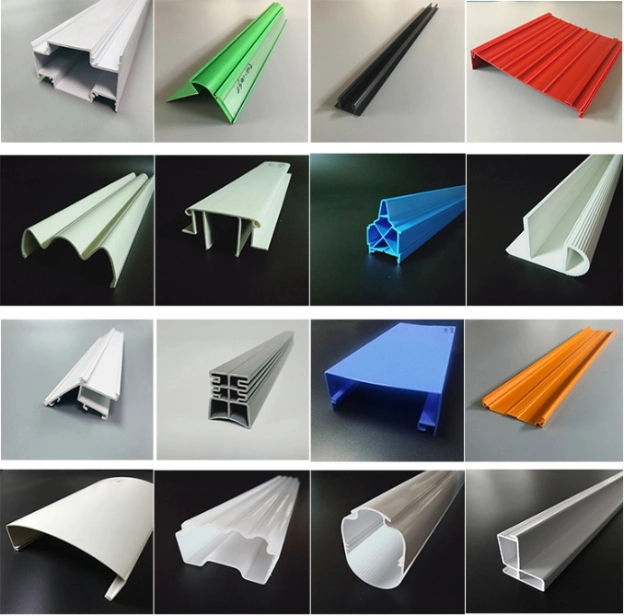

Some other PVC profiles made bu this machine

According to performance, it can be divided into hard and soft. Rigid PVC profiles are mostly used in construction, such as making PVC doors and windows, PVC floors, PVC pipes, etc.; soft PVC profiles are used for PVC hoses, power transmission cables, etc.

PVC profiles added with functional additives have anti-aging, anti-ultraviolet, corrosion resistance, high strength, low price, good heat preservation and heat insulation performance, can partially replace aluminum profiles, steel, etc., and have lower pollution than aluminum profiles.

Retelate products

Qingdao Tongsan Plastic Macxhinery CO.,LTD is professional for the Whole WPC production line with turnkey Project Service since 1997.We have all the WPC machines in factory stock and can be tested at anytime.

We have different type of WPC machines to make different WPC products from different raw material,

1, PVC WPC profile machine:

Material: 50%PVC+20% wood+20% caco3+ Chemical additives.

Product: WPC door frame, WPC wall panel, WPC decoration profiles indoor.

HGMSX series profile production line can continuously produce PVC/WPC profile,such as door and Window, wall panel, skirting etc.The production line consists of extruder, mould, calibrating platform, haul off and cutting machine and stacker.The extruder can produce PVC and WPC material profile by changing screw and mould.The calibrating platform adopts two-section structure and adopt double water tank, to ensure the stability of machine in production.The haul off and cutting machine is one body structure, the advantages of this unit are saving space and high precision cutting ,this unit also equip with dust collection system.The production line can optionally equip with PLC.

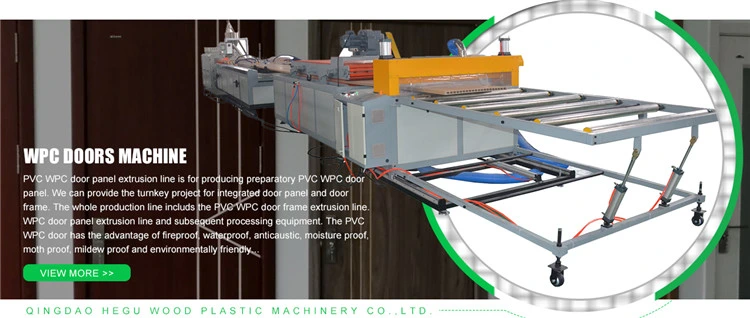

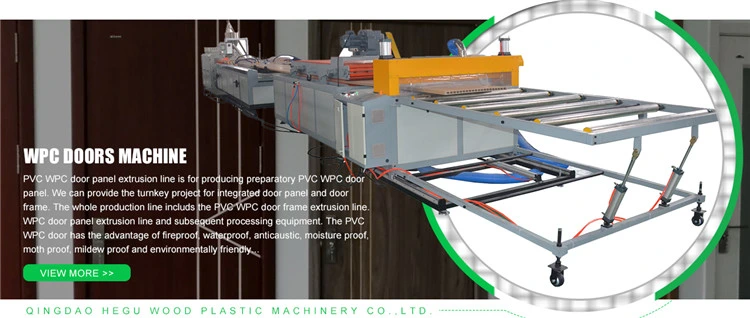

2, PVC WPC door machine:

Material:50% PVC+20% wood+20% caco3 +Chemical additives.

Product: Hollow Door panel, Cabinet Door, and other big profiles

HGMSM series door panel production line can continuously produce PVC/WPC door panel.The production line consists of extruder, mould, calibrating platform, Haul off machine, cutting machine and stacker.The extruder adopts specially designed screw, to ensure the door panel extrude steadily and foam uniformly.Calibrating platform adopts one body structure with adequate material.In case of shaking during production. Haul off machine adopts twin caterpillar structure ,the material of rubber block is silica gel.The haul off force is big and the speed is uniformly .Cutting machine adopts saw blade cutting, equipped with dust collection device.The production line runs stably and reliably during production.

3, PVC WPC board machine:

Material: 60% PVC+10% wood +20% CaCo3+ Chemical additives.

Product: Solid door panel, Furniture board, partition wall panel, decoration solid panel.

SJMSB series PVC/WPC foam board production line can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.The extruder adopts special screw. Calibrating platform equip width high efficiency cooling calibrator. Haul off machine adopts gear transmission to ensure uniform speed and high stabilize.The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

4, PP PE WPC granulating machiner

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

SHMS series granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

5,PP PE WPC profiles machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

Our service

Before order

1,Customized the production line and auxiliary machine according final products,and show all technical parameter to buyer,provide the turnkey project to customer.

2,Free machine running when customer visit our factory for quality inspection .

3, Design the mold drawing according customer requirements.

4,Design the machine layout and water and electricity layout according buy factory.

5,Any technical parameter support if customer in need.

In production

1,Confirm the mold drawing after received the down payment.

2,Start the product asap and updates the production status every 10 days.

3,Confirm the water and electricity layout and other accessories,ensure plant preparations well before the machines arrives.

4,Determine raw material preparation in customer factory.

5,Within 60 working days after receiving the advance payment, the seller shall notify the buyer to carry out the inspection

6,Arrange machine and mold testing to ensure customer or third party inspection satisfaction.

7,The seller shall complete the packing of the goods within 15 working days after receiving the full payment and be ready to ship.

8,The seller shall inform the buyer of the exact loading time and the buyer shall arrange to supervise the scope of the loading.

Machine in customer factory

1,After determining the date of the machine arrived customer's factory, arrange our professional engineer to install and debug the machine.

2,What the engineer should to do at the customer's plant:

2.1 Quickly install, debug the machine to normal operation and ensure product good quality products.

2,2 Provide the formula for production.

2.3 Teach workers how to use and maintain machines,solutions to daily problems in production

2.4Any production technical support for customer need.

3,Technical support online

If any problems when production we will reply online asap,within 24 hours to give the solution.

4, Warranty

4.1 Warranty period: 12 months from the first day of operation of the machine in the customer's warehouse

4.2 The seller shall guarantee that service and spare parts are free of charge throughout the warranty period of the equipment.

4.3Lifetime service: After the 12-month warranty clause, the seller should provide lifelong service for the goods sold and provide the buyer with the payment for the required spare parts.

RFQ Other products

1. single wall corrugated pipe making machine (ID 4.5mm- OD160mm);

2. double wall corruagted pipe making machine (ID 40mm- OD 300mm);

3. plastic pipe making machineID 12- OD 400mm) (PP,PE,PVC,PPR);

4.plastic sheet making machine (thickness=1-8mm) (ABS,HIPS,PP,PE,PMMA,GPPS);

5, Plastic hollow sheet making machine (1.5 -6 mm) (recycled plastic)

6. Plastic recycling granulating machine(PP,PE PVC)

7. WPC granulating machines

9,PVC WPC door panel making machine

10 ,wpc foam board making machine

11,PVC ceiling machine

12, Auxiliary machine:Crusher,milling machine,embossing machine,sanding machine,brushing machine,CNC engraving machine,laminating machine,hot stamping machine,PVC window processing machine, doors making machine.

About our company

Our customer

Our advantage

A.22 years manufacturer for plastic extruder machines,

B.50 professional engineer

C,5Q Strict quality control with CE

D.20+ years Professional Foreign Trade Service

E,Free machine running

F,Turnkey project service

Quality is Our Culture

Since 1997,Qingdao Tongsan has been focusing on plastic extrusion machines .Now have the corrugated pipe machine serious,plastic hollow sheet machines,plastic pipe serious,plastic sheet serious.Our professional engineer always committed to the improvement of machine quality

Customer satisfaction is our pursue

All behaviors will be based on better and more considerately meeting the needs of consumer to offer customized service.

Turnkey Service Provider

Let customer experience a sense of entitle,respond within 24 hours,solve problem within 48 hours.We will work 24hours*7days for the after-sell service.

Pursuit of Excellence

Devoting to the research,development and production of various plastic extrusion machines.It is always making innovations and keeping up with the times.

Our Main Machine

Single wall corrugated pipe machineDoube wall corrugated pipe machine

The PVC foam board produced by our SJ65/132 extrusion line is a new type of environmentally friendly plastic material and a perfect substitute for wood and steel. Compared with wood, it has many advantages: light weight, good flexibility, flame retardant, alkali and acid resistance, moisture proof, waterproof, heat preservation, sound insulation, shock absorption, etc. The board can be photographed or printed in color. It has a variety of processing methods, such as nails, saws, planning, cementing, joining, etc.

feature:

1. Light weight, no water absorption, flame retardant and self-extinguishing

2. Sound insulation, heat insulation, sound absorption, heat preservation and corrosion protection.

3. Weatherproof, anti-vandalism, and can be shaped, molded, painted and screen printed.

4. No warpage and anti-fouling.

5. Non-corrosive, non-toxic and chemical resistant.

6. Tough, rigid, high impact strength.

7. Easy to clean and maintain.

1,Raw material mixer

Function:Mixing all raw materials together by hot mixer and so then can compound well,then cooling by the cold mixer prevent reaction.

Working process:Automatic loading feeder--6-10min hot mixing--10-15min cooling

In order to avoid pollution, the mixer needs to be alone in a room. In addition, the mixed raw materials can be stored in silos, then transported directly from the silo to the extruder.

2,PVC eaves rain gutter extrusion line

Function and working process:

Automatic loading ----Conical double screw extruder ---die mould---calibrator platform cooling----haul off device---Automatic cutting machine---Productus stacker

Special design screw for PVC powder extrusion,SIEMENS brand motor,famous brand gear box,with automatic loading and feeder

In order to cooling the products well,adopt the cauum pump and water pump,two sets water tank.All parts contact with water are made by stainless steell.

The haul off device clamped the products by the rubber block, then the movement of the rubber block pulls the product forward.

Automatic cutting machine can customized cut the final products at the required length .

It has the functions of measuring cutting and accumulative counting.It adopt with the dust collector avoid pollution.

Carry and support the cutted final product, and then arrange neatly.

Made of stainless steel, the slide rail is equipped with a rubber protective layer.

3,PVC eaves rain gutter mould

We can design the mold according your requirments,mould material: 3cr17,the special high-quality mold steel

We offer the mold for 60 /65/80/85 series PVC window and doors,the co-extrusion type for ASA surface and sealing rubber.

4,SWP360 Plastic crusher

The crusher used to recycling the waste products ,then cutting them into small flakes.

5,SMW-500 high speed PVC Grinding machine

The high speed PVC grinding machine used to milling the PVC flakes into powder,so the waste PVC products can be recycled use.

6,20HP Water chiller :HANGKANG ANGES brand,Danfoss compressor

Cooling the recycle water which used to cooling the products,

so it can increace the production speed and get good products surface.

7,30A air compressor

Provide the air to the mold,cylinder for haul off device,cutter,and stacker

Plastic PVC foamed profiles making machine details

PVC foamed profile making machine model

Model | Extruder size | Main motor power | Max.product width | Production capacity |

TS-300 | SJSZ51/105 | 22KW | 250mm | 120-180 kg/h |

TS-600 | SJSZ65/132 | 37KW | 600mm | 150-240 kg/h |

1,Main extruder

Extruder type: Conical double screw extruder

Model: SJMS 51/105 or SJMS 65/132

Motor: 22Kw / 37kw

feeder: Auto feeding

Die head: one set

calibrators: three pieces

Mold heating: one set four pieces

water tank: one piece

Cooling type: vacuum cooling and water cooling

Cooling machine length: 6 meters

water pump: 1 set

vacuum pump: 1 set

Double caterpillar: rubber caterpillar

Power: 2.2kw

Window glass: moveable

Cutting power: 1.1kw

Cutting by automatical control

Length fixed as required, adjustable

Features compared with wood and WPC

FEATURES COMPARED WITH WOOD AND WPC | WOOD | WPC (WOOD PLASTIC COMPOSITS) | PVC FOAM BOARD |

Preservative-free: | No | Yes | Yes |

impervious to moisture, doesn't mould: | No | Some | Yes |

Impervious to insects: | No | Some | Yes |

Fire-retardant (self-extinguishing): | No | No | Yes |

UV resistant: | No | No | Yes |

Light weight: | No | No | Yes |

Won't swell when screwing or nailing: | Yes | Yes | Yes |

Not easy to scratch: | No | No | Yes |

Easy to clean, virtually maintenance free | No | Part | Yes |

100% recyclable | Yes | Yes | Yes |

Application for PVC foamed profiles

1.PVC foamed chamfer strip is a triangular strip of rigid PVC or Foam PVC, nailed to concrete formwork in various places: outside corners, around window or door openings, at the top of an exposed wall, etc.

2.Fireproof, waterproof, antiseptic, no broken by nailing, no broken by Curving, replacing Wood

Some other PVC profiles made bu this machine

According to performance, it can be divided into hard and soft. Rigid PVC profiles are mostly used in construction, such as making PVC doors and windows, PVC floors, PVC pipes, etc.; soft PVC profiles are used for PVC hoses, power transmission cables, etc.

PVC profiles added with functional additives have anti-aging, anti-ultraviolet, corrosion resistance, high strength, low price, good heat preservation and heat insulation performance, can partially replace aluminum profiles, steel, etc., and have lower pollution than aluminum profiles.

Retelate products

Qingdao Tongsan Plastic Macxhinery CO.,LTD is professional for the Whole WPC production line with turnkey Project Service since 1997.We have all the WPC machines in factory stock and can be tested at anytime.

We have different type of WPC machines to make different WPC products from different raw material,

1, PVC WPC profile machine:

Material: 50%PVC+20% wood+20% caco3+ Chemical additives.

Product: WPC door frame, WPC wall panel, WPC decoration profiles indoor.

HGMSX series profile production line can continuously produce PVC/WPC profile,such as door and Window, wall panel, skirting etc.The production line consists of extruder, mould, calibrating platform, haul off and cutting machine and stacker.The extruder can produce PVC and WPC material profile by changing screw and mould.The calibrating platform adopts two-section structure and adopt double water tank, to ensure the stability of machine in production.The haul off and cutting machine is one body structure, the advantages of this unit are saving space and high precision cutting ,this unit also equip with dust collection system.The production line can optionally equip with PLC.

| Model | Profile Width | Extruder model | Motor power | Max.extrusion capacity | Calibrating platform length |

| HGMSC-200 | 200mm | 51/105 | 22kw | 100-120kg/h | 4000mm |

| HGMSC-300 | 300mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSC-400 | 400mm | 65/132 | 37kw | 150-180kg/h | 6000mm |

| HGMSCD-300 | 600mm | 65/132 | 37kw | 150-180kg/h | 8000mm |

| HGMSC-600 | 600mm | 65/13 or 80/156 | 37 or 75kw | 150-350kg/h | 6000mm |

2, PVC WPC door machine:

Material:50% PVC+20% wood+20% caco3 +Chemical additives.

Product: Hollow Door panel, Cabinet Door, and other big profiles

HGMSM series door panel production line can continuously produce PVC/WPC door panel.The production line consists of extruder, mould, calibrating platform, Haul off machine, cutting machine and stacker.The extruder adopts specially designed screw, to ensure the door panel extrude steadily and foam uniformly.Calibrating platform adopts one body structure with adequate material.In case of shaking during production. Haul off machine adopts twin caterpillar structure ,the material of rubber block is silica gel.The haul off force is big and the speed is uniformly .Cutting machine adopts saw blade cutting, equipped with dust collection device.The production line runs stably and reliably during production.

| Model | Door panel width | Door panel thickness | Extruder model | Motor power | Max extrusion capacity | Calibrating mould section |

| HGMSM-800 | 800 | 20-50mm | SJMS 80/156 | 75kw | 350-380kg/h | 2 |

| HGMSM-1000 | 1000 | 20-50mm | SJMS 92/188 | 110kw | 450-500kg/h | 3 |

| HGMSM-1200 | 1200 | 20-50mm | SJMS 92/188 | 110kw | 450-500kg/h | 3 |

3, PVC WPC board machine:

Material: 60% PVC+10% wood +20% CaCo3+ Chemical additives.

Product: Solid door panel, Furniture board, partition wall panel, decoration solid panel.

SJMSB series PVC/WPC foam board production line can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.The extruder adopts special screw. Calibrating platform equip width high efficiency cooling calibrator. Haul off machine adopts gear transmission to ensure uniform speed and high stabilize.The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

| Model | SJMSB-80/156 | SJMSB-80/173 | SJMSB-92/188 |

| Board thickness | 5-18mm | 3-30mm | 20-40mm |

| Board width | 1220mm | 1220mm | 1220mm |

| Max extrusion capacity | 350-380kg/h | 420-450kg/h | 500-550kg/h |

| Motor power | 75kw | 90kw | 110kw |

4, PP PE WPC granulating machiner

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

SHMS series granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

| Model | L/D ratio | Max.capacity | Motor power | Suitable material | Max.rotating speed | Wood powder percentage |

| SHMS-65 | 40:1 | 200-220kg/h | 75kw | Pe+wood powder | 500r/min | ≤75% |

| SHMS-75 | 40:1 | 300-350kg/h | 90kw | Pe+wood powder | 500r/min | ≤75% |

| SHMS-90 | 40:1 | 500-600kg/h | 132kw | Pe+wood powder | 500r/min | ≤75% |

5,PP PE WPC profiles machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

| Model | HGMSE-65 | HGMSE-80 |

| Extruder model | SJMS65/132 | SJMS 80/156 |

| Motor power | 37kw | 75kw |

| Mac.Extrusion capacity | 140-160kg/h | 220-250kg/h |

| Co-extruder(Optional) | SJ35/28 | SJ45/28 |

Our service

Before order

1,Customized the production line and auxiliary machine according final products,and show all technical parameter to buyer,provide the turnkey project to customer.

2,Free machine running when customer visit our factory for quality inspection .

3, Design the mold drawing according customer requirements.

4,Design the machine layout and water and electricity layout according buy factory.

5,Any technical parameter support if customer in need.

In production

1,Confirm the mold drawing after received the down payment.

2,Start the product asap and updates the production status every 10 days.

3,Confirm the water and electricity layout and other accessories,ensure plant preparations well before the machines arrives.

4,Determine raw material preparation in customer factory.

5,Within 60 working days after receiving the advance payment, the seller shall notify the buyer to carry out the inspection

6,Arrange machine and mold testing to ensure customer or third party inspection satisfaction.

7,The seller shall complete the packing of the goods within 15 working days after receiving the full payment and be ready to ship.

8,The seller shall inform the buyer of the exact loading time and the buyer shall arrange to supervise the scope of the loading.

Machine in customer factory

1,After determining the date of the machine arrived customer's factory, arrange our professional engineer to install and debug the machine.

2,What the engineer should to do at the customer's plant:

2.1 Quickly install, debug the machine to normal operation and ensure product good quality products.

2,2 Provide the formula for production.

2.3 Teach workers how to use and maintain machines,solutions to daily problems in production

2.4Any production technical support for customer need.

3,Technical support online

If any problems when production we will reply online asap,within 24 hours to give the solution.

4, Warranty

4.1 Warranty period: 12 months from the first day of operation of the machine in the customer's warehouse

4.2 The seller shall guarantee that service and spare parts are free of charge throughout the warranty period of the equipment.

4.3Lifetime service: After the 12-month warranty clause, the seller should provide lifelong service for the goods sold and provide the buyer with the payment for the required spare parts.

RFQ

1. Why choose us

We are the first manufacturer in Qingdao to develop plastic extruders. We have 22 years of experience in mechanical manufacturing. What we pursue is machine quality and customer satisfaction. Please make sure that we have the strength to provide you with high-quality machines and perfect services.

2. What service do we provide?

Turnkry project service, 24-hour online technical service.

3. Payment terms

30% of the total amount should be paid by wire transfer as a down payment, and the balance (70% of the total amount) should be paid (at sight) before the delivery of the wire transfer or irrevocable letter of credit

4. Delivery terms:

4.1 Delivery terms: FOB Qingdao Port.

4.2 Delivery deadline: within 60 working days after receiving the advance payment, the seller shall notify the buyer to inspect. The seller should complete the packaging of the goods within 15 working days after receiving the full payment and be ready for shipment.

4.3 Loading supervision: The seller should inform the buyer of the exact loading time, and the buyer should arrange a time for supervision of the loading.

5. Warranty terms:

5.1 Warranty period: 12 months from the first day of operation of the machine in the customer's warehouse

5.2 The seller shall guarantee that the service and spare parts are free during the entire equipment warranty period.

5.3 LIFELONG service: The seller shall provide LIFELONG service (sold goods) after the 12-month warranty, and the buyer shall pay for the required spare parts.

6. Inspection:

After the machine is completed, the seller should notify the buyer to inspect before delivery, and the seller guarantees that all the goods sold are of good quality. The seller does not bear the material cost of the machine inspection in the seller's factory. The buyer should come to the seller's factory for inspection, or the buyer can invite any third party to enter the seller's factory for inspection.

7. Installation and equipment debugging:

If the buyer needs it, the seller should send a team of technicians to the buyer's factory for installation and testing, and the buyer should release the knowledge of the entire food/location and surrounding traces (aircraft, food, hotel, etc.), and charge the engineer $100 /Day/engineer's cost.

We are the first manufacturer in Qingdao to develop plastic extruders. We have 22 years of experience in mechanical manufacturing. What we pursue is machine quality and customer satisfaction. Please make sure that we have the strength to provide you with high-quality machines and perfect services.

2. What service do we provide?

Turnkry project service, 24-hour online technical service.

3. Payment terms

30% of the total amount should be paid by wire transfer as a down payment, and the balance (70% of the total amount) should be paid (at sight) before the delivery of the wire transfer or irrevocable letter of credit

4. Delivery terms:

4.1 Delivery terms: FOB Qingdao Port.

4.2 Delivery deadline: within 60 working days after receiving the advance payment, the seller shall notify the buyer to inspect. The seller should complete the packaging of the goods within 15 working days after receiving the full payment and be ready for shipment.

4.3 Loading supervision: The seller should inform the buyer of the exact loading time, and the buyer should arrange a time for supervision of the loading.

5. Warranty terms:

5.1 Warranty period: 12 months from the first day of operation of the machine in the customer's warehouse

5.2 The seller shall guarantee that the service and spare parts are free during the entire equipment warranty period.

5.3 LIFELONG service: The seller shall provide LIFELONG service (sold goods) after the 12-month warranty, and the buyer shall pay for the required spare parts.

6. Inspection:

After the machine is completed, the seller should notify the buyer to inspect before delivery, and the seller guarantees that all the goods sold are of good quality. The seller does not bear the material cost of the machine inspection in the seller's factory. The buyer should come to the seller's factory for inspection, or the buyer can invite any third party to enter the seller's factory for inspection.

7. Installation and equipment debugging:

If the buyer needs it, the seller should send a team of technicians to the buyer's factory for installation and testing, and the buyer should release the knowledge of the entire food/location and surrounding traces (aircraft, food, hotel, etc.), and charge the engineer $100 /Day/engineer's cost.

1. single wall corrugated pipe making machine (ID 4.5mm- OD160mm);

2. double wall corruagted pipe making machine (ID 40mm- OD 300mm);

3. plastic pipe making machineID 12- OD 400mm) (PP,PE,PVC,PPR);

4.plastic sheet making machine (thickness=1-8mm) (ABS,HIPS,PP,PE,PMMA,GPPS);

5, Plastic hollow sheet making machine (1.5 -6 mm) (recycled plastic)

6. Plastic recycling granulating machine(PP,PE PVC)

7. WPC granulating machines

8.PVC WPC window profiles,door frames,decking making machine

9,PVC WPC door panel making machine

10 ,wpc foam board making machine

11,PVC ceiling machine

12, Auxiliary machine:Crusher,milling machine,embossing machine,sanding machine,brushing machine,CNC engraving machine,laminating machine,hot stamping machine,PVC window processing machine, doors making machine.

About our company

Our customer

| Asia | ||||

| Afghanistan | Bahrain | Bangladesh | India | Indonesia |

| Iran | Kuwait | Malaysia | Mongolia | Oman |

| Pakistan | Qatar | Saudi Arabia | SriLanka | Turkey |

| UAE | Vietnamese | Yemen | South Korea | |

| Africa | ||||

| Algeria | Burundi | Cameroon | Botswana | Congo |

| Egypt | Djibouti | Ethiopia | South Africa | Cote Divoire |

| Kenya | Libya | Mali | Mauritius | Morocco |

| Nigeria | Sudan | Tanzania | Tunisia | Uganda |

| Europe | ||||

| Belgium | Bulgaria | Poland | Belarus | Georgia |

| Kazakhstan | Kyrgyzstan | Uzbekistan | Tajikistan | Turkmenistan |

| Ukraine | Lithuania | |||

| America | ||||

| Chile | Colombia | Dominica | Ecuador | Mexico |

| Peru | Uruguay | Venezuela | ||

Our advantage

A.22 years manufacturer for plastic extruder machines,

B.50 professional engineer

C,5Q Strict quality control with CE

D.20+ years Professional Foreign Trade Service

E,Free machine running

F,Turnkey project service

Quality is Our Culture

Since 1997,Qingdao Tongsan has been focusing on plastic extrusion machines .Now have the corrugated pipe machine serious,plastic hollow sheet machines,plastic pipe serious,plastic sheet serious.Our professional engineer always committed to the improvement of machine quality

Customer satisfaction is our pursue

All behaviors will be based on better and more considerately meeting the needs of consumer to offer customized service.

Turnkey Service Provider

Let customer experience a sense of entitle,respond within 24 hours,solve problem within 48 hours.We will work 24hours*7days for the after-sell service.

Pursuit of Excellence

Devoting to the research,development and production of various plastic extrusion machines.It is always making innovations and keeping up with the times.

Our Main Machine

Single wall corrugated pipe machine