Plastic foam board machinery pvc foam board making machine

PART 1 INTRODUCTION:

This pvc plastic foam board extrusion line is specially designed to produce kinds of applications of pvc free foam board, with properties of acoustic insulation, acoustic absorption, heat insulation, heat presveration and so on, which can be used safely with characteristics of flame retardancy, self-extinguishing and fireproofing.

PART 2: THIS LINE CONSISTS OF:

1. Spring feeding machine 1 set

2. Conical twin screw extruder 1 set

3. T-type die head 1 set

4. Three roller calendars and rollers thermocontrolling machine 1 set

5. Cooling frame and edge cutting device 1 set

6. Haul off machine 1 set

7. Longitudinal cutting machine 1 set

8. Cross cutting machine 1 set

9. Stacker

Other optional parts:

10. High speed hot and cold mixer 1 set

11. Plastic crusher 1 set

12. Plastic pulverizer 1 set

13. Water chiller 1 set

PART 3 BOARD APPLICATION:

PVC free foamed board is widely used in bus and train roofing, core layer of box, advertisment board, decoration board, furniture board, construction decoration material, advertisement board, upholstery for train, exhibition board, etc.

PART 4: DELIVERY, PAYMENT AND AFTER SALES SERVICE:

1. Delivery time: 70 days

2. Payment: 40% T/T for the prepayment, 60% T/T for the downpayment before delivery

3. After sale service: We will send our engineers to customers factory to install and test the machines, and train their workers.

4. Guaranteed time: 18 months for the machenical parts, 12 months for the electrical parts.

PART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

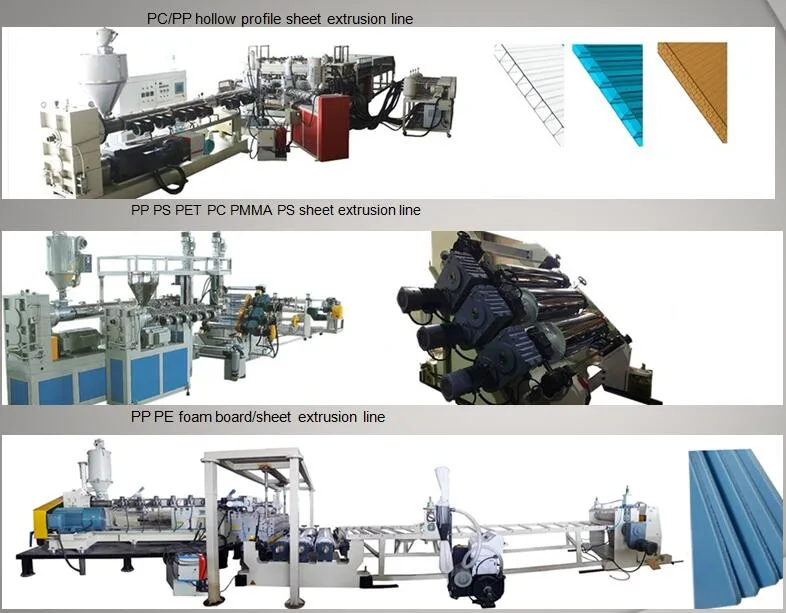

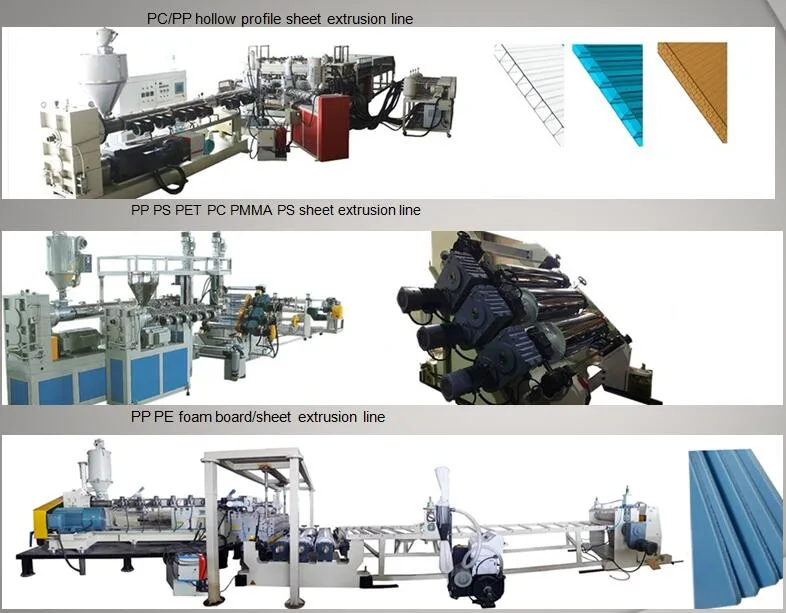

PART 9 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

Best regards!

Sincerely yours,

Lilly Zhou, Sales Manager

Qingdao Leader Machinery Co.,Ltd

Address: South of Yangjialin, Beiguan, Jiaozhou, Qingdao, China

Postal No.: 266300

Tel/fax: 0086-532-86620998, 86622373, 82278979

Website: http://extruder-cn.en.made-in-china.com

mob: 0086-152 6623 8607

PART 1 INTRODUCTION:

This pvc plastic foam board extrusion line is specially designed to produce kinds of applications of pvc free foam board, with properties of acoustic insulation, acoustic absorption, heat insulation, heat presveration and so on, which can be used safely with characteristics of flame retardancy, self-extinguishing and fireproofing.

PART 2: THIS LINE CONSISTS OF:

1. Spring feeding machine 1 set

2. Conical twin screw extruder 1 set

3. T-type die head 1 set

4. Three roller calendars and rollers thermocontrolling machine 1 set

5. Cooling frame and edge cutting device 1 set

6. Haul off machine 1 set

7. Longitudinal cutting machine 1 set

8. Cross cutting machine 1 set

9. Stacker

Other optional parts:

10. High speed hot and cold mixer 1 set

11. Plastic crusher 1 set

12. Plastic pulverizer 1 set

13. Water chiller 1 set

PART 3 BOARD APPLICATION:

PVC free foamed board is widely used in bus and train roofing, core layer of box, advertisment board, decoration board, furniture board, construction decoration material, advertisement board, upholstery for train, exhibition board, etc.

PART 4: DELIVERY, PAYMENT AND AFTER SALES SERVICE:

1. Delivery time: 70 days

2. Payment: 40% T/T for the prepayment, 60% T/T for the downpayment before delivery

3. After sale service: We will send our engineers to customers factory to install and test the machines, and train their workers.

4. Guaranteed time: 18 months for the machenical parts, 12 months for the electrical parts.

| Board width | 1000mm | 1220mm | 1560mm | 2050mm |

| Board thickness | 1-10mm | 1-18mm | 1-12mm | 1-10mm |

| Extruder model | SJSZ65/132 | SJSZ80/156 | SJSZ80/156 | SJSZ80/156 |

| Max capacity | 250kg/h | 350kg/h | 400kg/h | 400kg/h |

| Main motor power | 37kw | 55kw | 75kw | 75kw |

PART 6 COMPANY CERTIFICATIONS:

PART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

PART 9 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/HIPS sheet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

Best regards!

Sincerely yours,

Lilly Zhou, Sales Manager

Qingdao Leader Machinery Co.,Ltd

Address: South of Yangjialin, Beiguan, Jiaozhou, Qingdao, China

Postal No.: 266300

Tel/fax: 0086-532-86620998, 86622373, 82278979

Website: http://extruder-cn.en.made-in-china.com

mob: 0086-152 6623 8607