New type molten metal filter Silicon Carbide Ceramic Foam Filters

Description :

ceramic foam filter is prepared from an open cell, flexible foam material having a plurality of interconnected voids surrounded by a web of the flexible foam material. Typical materials which may be used include polymeric foams, such as polyurethane and cellulosic foams. Generally, any combustible organic plastic foam may be used which has resilience and the ability to recover to original shape. The foam must be burned out or volatilized below the firing temperature of the ceramic material which is employed.

The basic materials of the ceramic foam filter are three kinds of silicon carbide, zirconium oxide and aluminum oxide. Silicon Carbide Ceramic Foam Filters have excellent strength and high temperature impact resistance and chemical corrosion. It can withstand high temperatures up to about 1560 °C.They are therefore suitable for the casting of all copper alloys and cast iron.

The foam ceramic filter has excellent filtering effect on copper water or aluminum water, and utilizes a three-dimensional structure to effectively remove oxide inclusions and other non-metallic inclusions by blocking capture adsorption.

Whether it is gray iron, ductile iron or shaft body, cylinder or complex large parts, precision metal parts are filtered, the product quality will get satisfactory results.

Silicon Carbide Ceramic Foam Filters Application

The foam ceramic filter is also suitable for copper alloys such as copper, bronze, brass, etc., to reduce the turbulence of the copper liquid and to rectify and purify the molten copper liquid.

Particularly valuable is that the copper castings that have been purified by filtration have a significant life extension in high-demand or harsh environments such as turbines and chemical parts of marine vessels, and have good effects on cast copper parts with surface polishing requirements.

Foam ceramic filters also play an important role in the traditional copper industry and electric and electronic copper industry and continuous casting and rolling processes.

Since copper and alloys, including zinc alloys, have a greater specific gravity and produce greater thermal shock during casting, the use of silicon carbide foam ceramic filters in the copper casting process is generally strictly sized.

FEATURES

Silicon carbide foam ceramic filters are used in the production of ductile and grey iron castings,effectively trapping non-metallic inclusions in the metal stream. Resulting improvements are lower scrap,increased yield, mechanical properties, good finish and machinability.

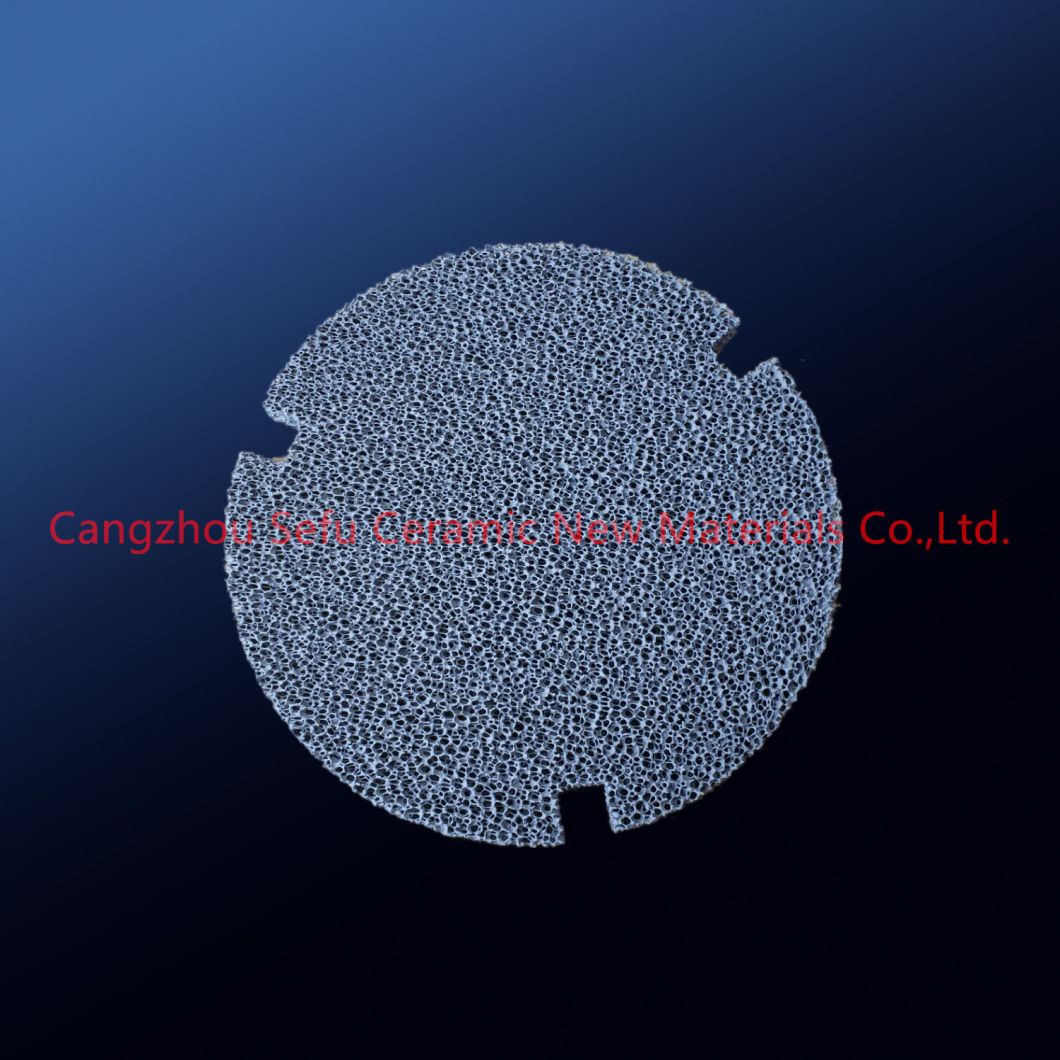

The placement of the ceramic foam filter in the gating system

silicon carbide ceramic foamfilter is characterized by high porosity and mechanochemical stability and excellentresistance to thermal shock and corrosion from moltenmetal. It can effectively remove inclusions, reducetrapped gas and provide laminar flow when iron molten metal filtrated, ceramicfoam filter is machined to tight dimensional tolerance during production,this combination of physical properties and precise tolerance make them firstchoice for iron molten metal filtration.The filter is generally installed in the gating system: Bottom of sprue,Runner,Ingate and in the Pouring cup . Round filters are more commonly used in direct pour applications where they are located inside an insulating or exothermic feeder sleeve, with optimum feed characteristics being achieved when the filter is allowed to float after pouring.

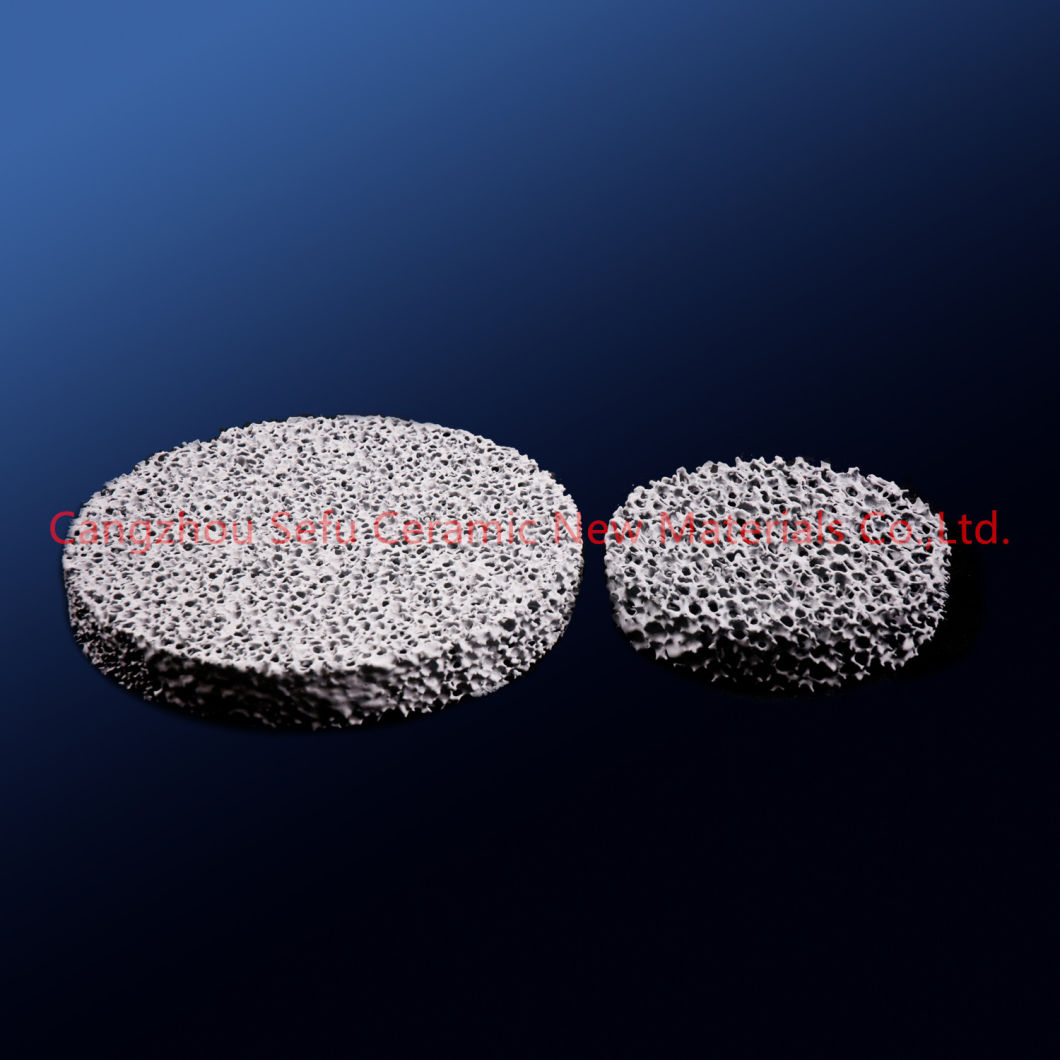

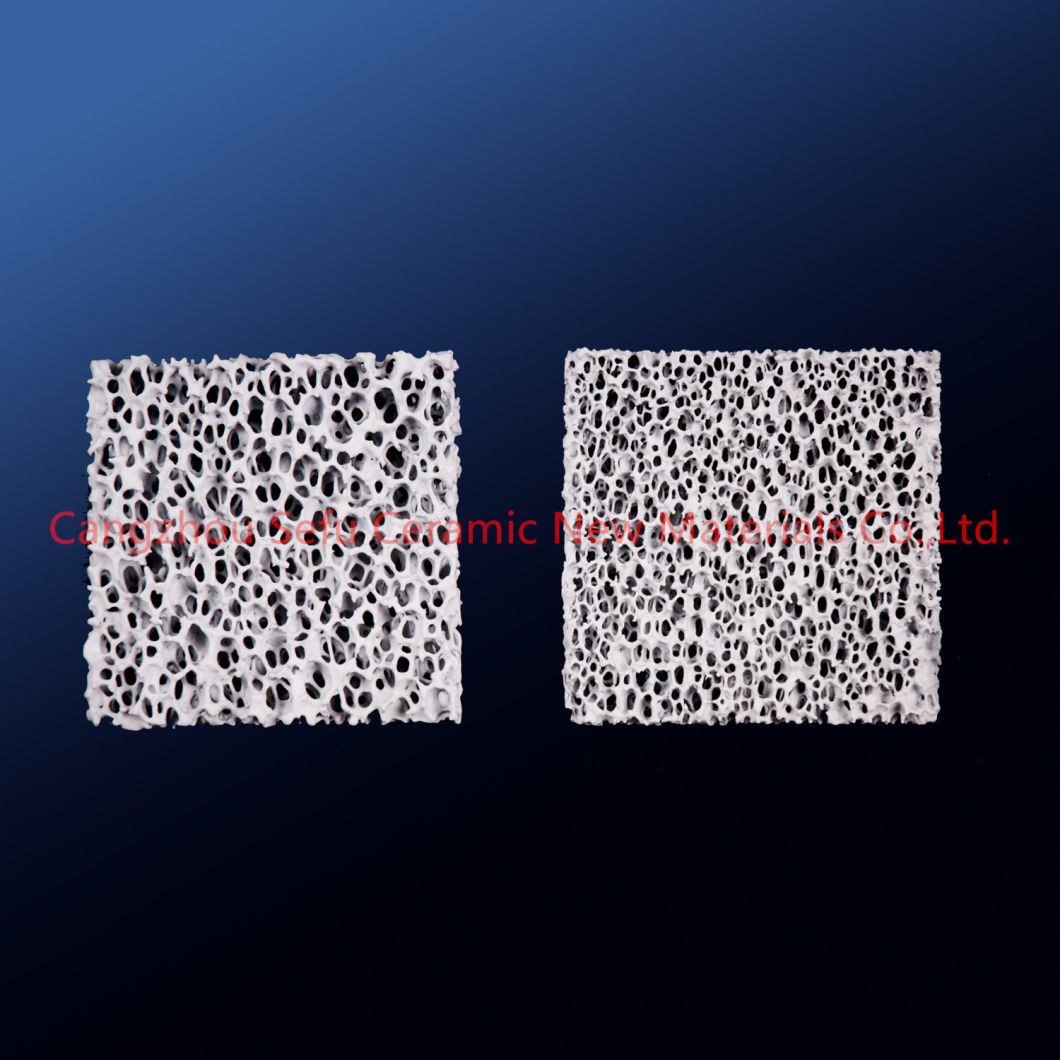

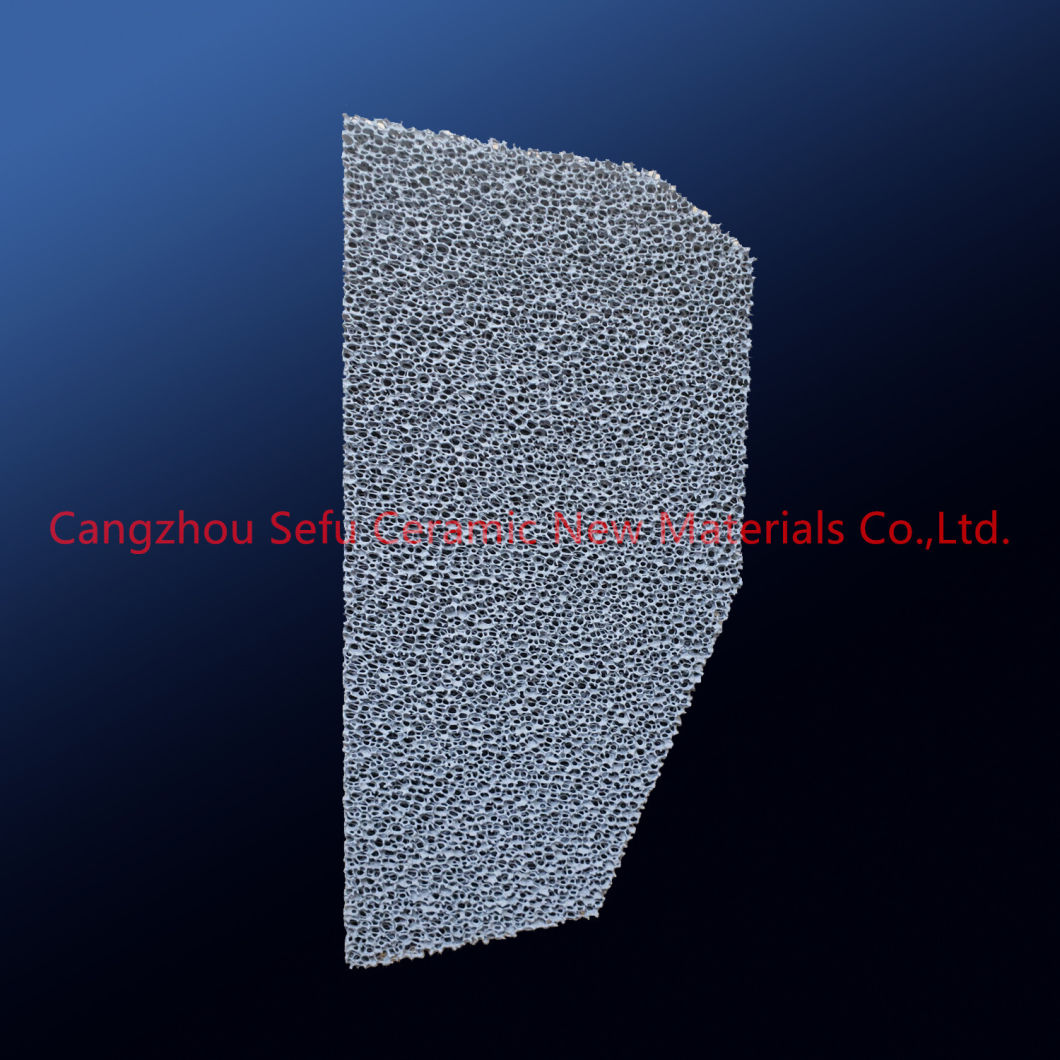

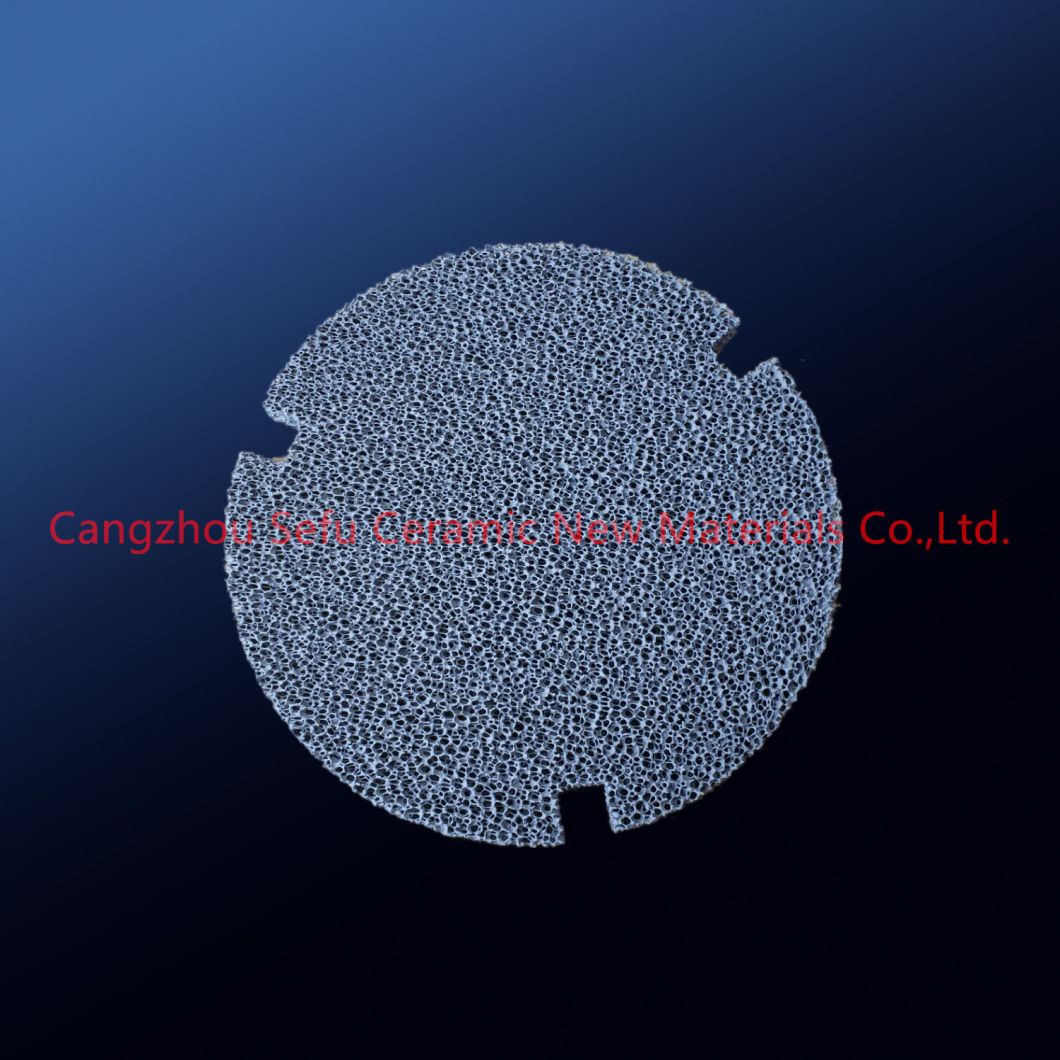

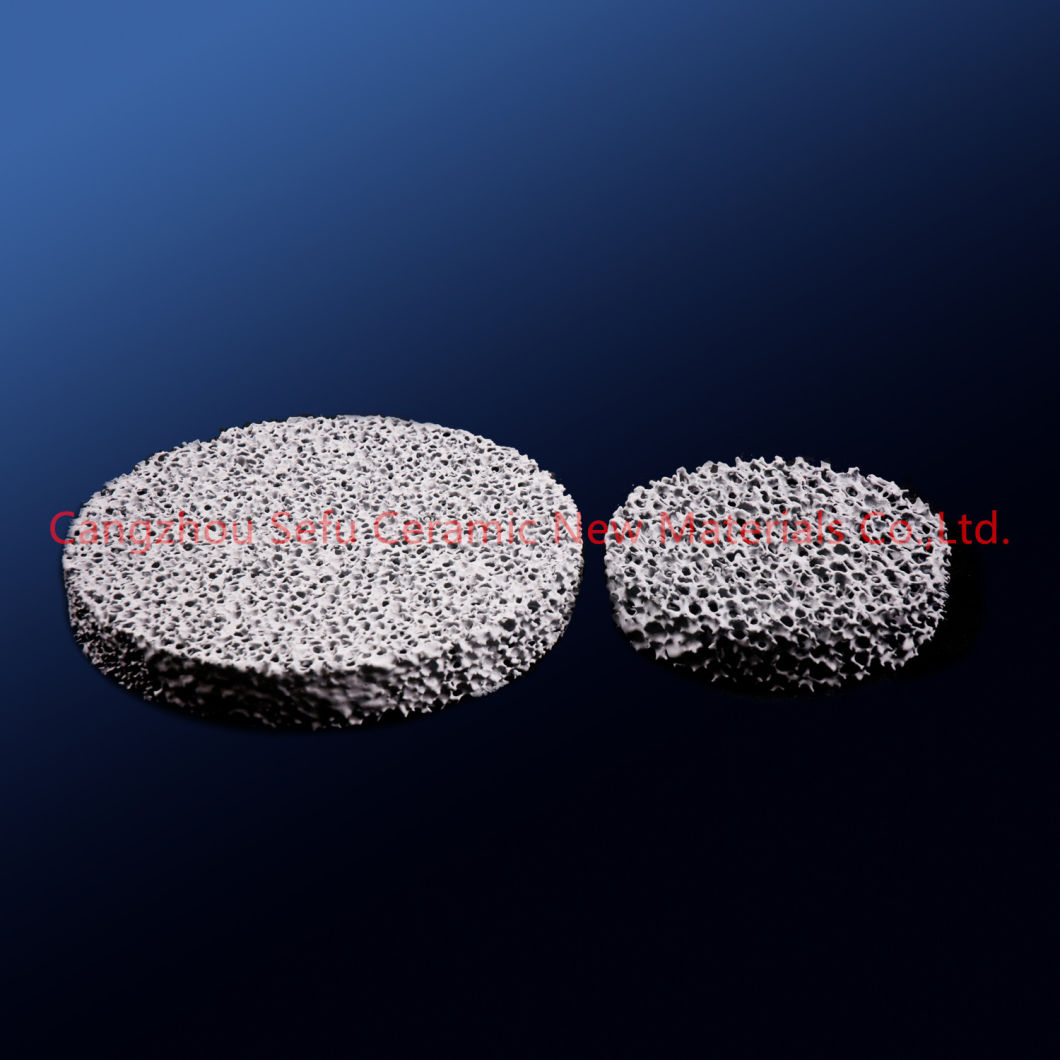

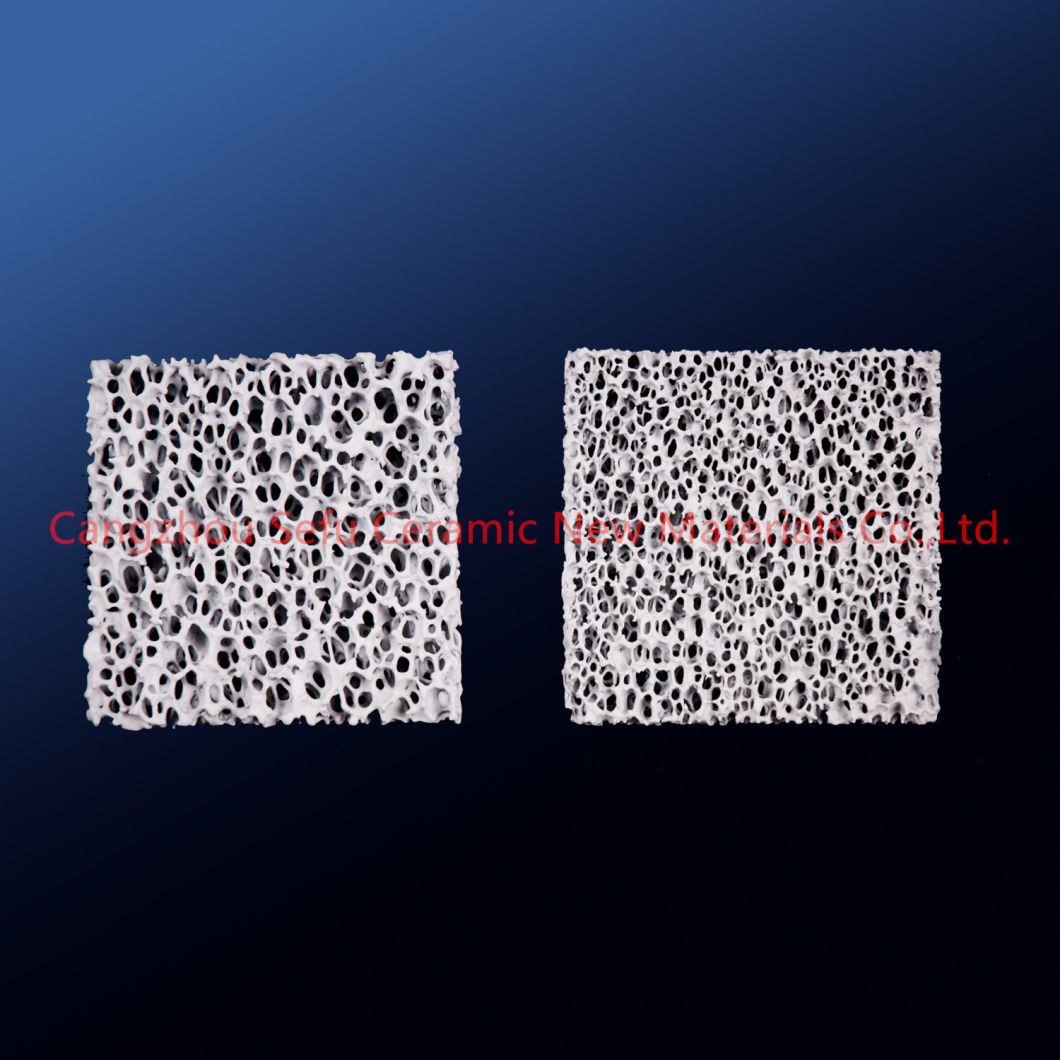

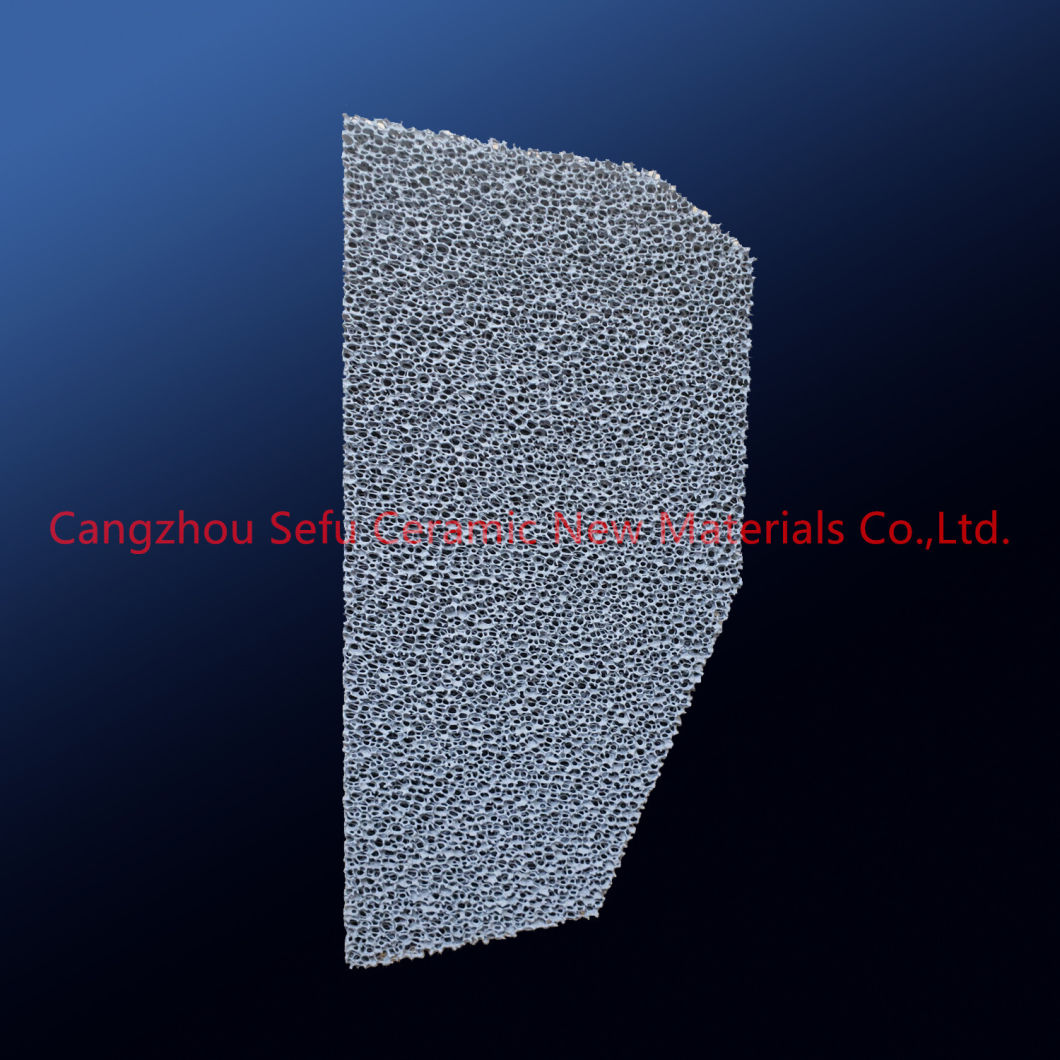

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceramic New Materials Co.,Ltd.

Description :

ceramic foam filter is prepared from an open cell, flexible foam material having a plurality of interconnected voids surrounded by a web of the flexible foam material. Typical materials which may be used include polymeric foams, such as polyurethane and cellulosic foams. Generally, any combustible organic plastic foam may be used which has resilience and the ability to recover to original shape. The foam must be burned out or volatilized below the firing temperature of the ceramic material which is employed.

The basic materials of the ceramic foam filter are three kinds of silicon carbide, zirconium oxide and aluminum oxide. Silicon Carbide Ceramic Foam Filters have excellent strength and high temperature impact resistance and chemical corrosion. It can withstand high temperatures up to about 1560 °C.They are therefore suitable for the casting of all copper alloys and cast iron.

The foam ceramic filter has excellent filtering effect on copper water or aluminum water, and utilizes a three-dimensional structure to effectively remove oxide inclusions and other non-metallic inclusions by blocking capture adsorption.

Whether it is gray iron, ductile iron or shaft body, cylinder or complex large parts, precision metal parts are filtered, the product quality will get satisfactory results.

Silicon Carbide Ceramic Foam Filters Application

The foam ceramic filter is also suitable for copper alloys such as copper, bronze, brass, etc., to reduce the turbulence of the copper liquid and to rectify and purify the molten copper liquid.

Particularly valuable is that the copper castings that have been purified by filtration have a significant life extension in high-demand or harsh environments such as turbines and chemical parts of marine vessels, and have good effects on cast copper parts with surface polishing requirements.

Foam ceramic filters also play an important role in the traditional copper industry and electric and electronic copper industry and continuous casting and rolling processes.

Since copper and alloys, including zinc alloys, have a greater specific gravity and produce greater thermal shock during casting, the use of silicon carbide foam ceramic filters in the copper casting process is generally strictly sized.

FEATURES

Silicon carbide foam ceramic filters are used in the production of ductile and grey iron castings,effectively trapping non-metallic inclusions in the metal stream. Resulting improvements are lower scrap,increased yield, mechanical properties, good finish and machinability.

- Reduce the defect rate of the inclusion of the defective products,and reduce the defect of the inclusion of 50% or more.

- Improve the processing performance of the casting:the tool life is improved by more than 30%

- Improve the mechanical properties of casting:mechanical properties increased by more than 10%.

- Improve casting technology production rate:the rate of production rate increased by more than 10%

The placement of the ceramic foam filter in the gating system

silicon carbide ceramic foamfilter is characterized by high porosity and mechanochemical stability and excellentresistance to thermal shock and corrosion from moltenmetal. It can effectively remove inclusions, reducetrapped gas and provide laminar flow when iron molten metal filtrated, ceramicfoam filter is machined to tight dimensional tolerance during production,this combination of physical properties and precise tolerance make them firstchoice for iron molten metal filtration.The filter is generally installed in the gating system: Bottom of sprue,Runner,Ingate and in the Pouring cup . Round filters are more commonly used in direct pour applications where they are located inside an insulating or exothermic feeder sleeve, with optimum feed characteristics being achieved when the filter is allowed to float after pouring.

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

- Inside packing: Filters are put in small box and Layered packaging. There is cardboard between each layer.

- Outside packing: Cartons&Pallets. Three layer corrugated cartons and export special pallets .

- The mark on cartons can be designed according to the customer's request.

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceramic New Materials Co.,Ltd.