HVAC Systems.

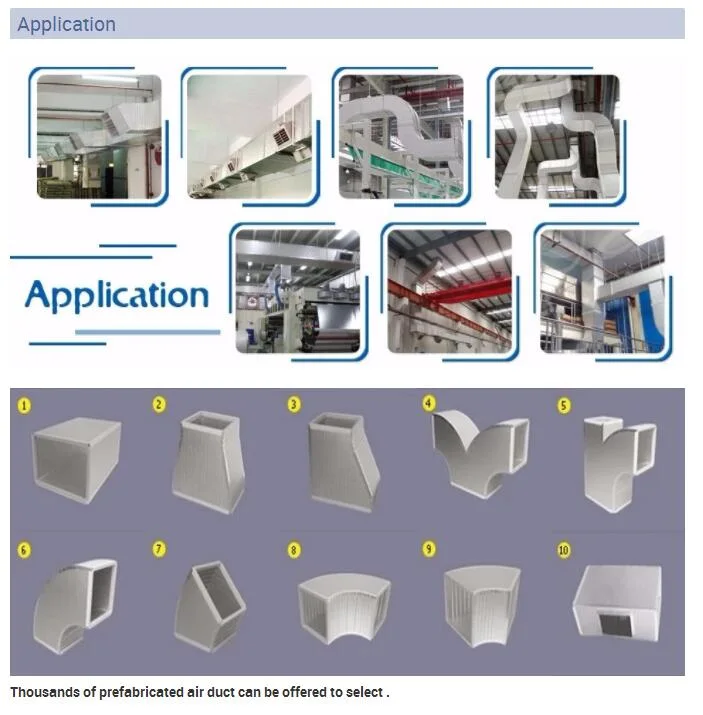

The W.T Pre-insulated Duct Panel can offers a high performance light weight and good ductwork system that requires only a few single fix and installation process. It is widely used in the ventilation systems of central air conditioning units in hospital, hotel, market,mall, airport, and so on.

| Item | Unit | Specification |

| Panel Structure | Aluminum foil/Phenolic or PIR/Aluminum foil | |

| Standard Panel Size | mm | 3950*1200*20 |

| Fireproof | grade | BS476 CLASS O |

| Alu. Foil Thickness | micron | 40/60/80 |

| Foam Density | kg/m3 | 40/50/60 |

| Thermal Conductivity | w/m.k | 0.02-0.025 |

| Compressing Strength | Mpa | 0.2 |

| Bending Strength | Mpa | 2 |

| Water Absorption | % | ≤0.1 |

| Dimension Change | % | 0.3 |

| Working Temperature | ºC | -150 to +120 |

| Maximum Allowable Wind Velocity | m/s | ≤12 |

| Continuous Running Maximum Temperature | ºC | ≤70 |

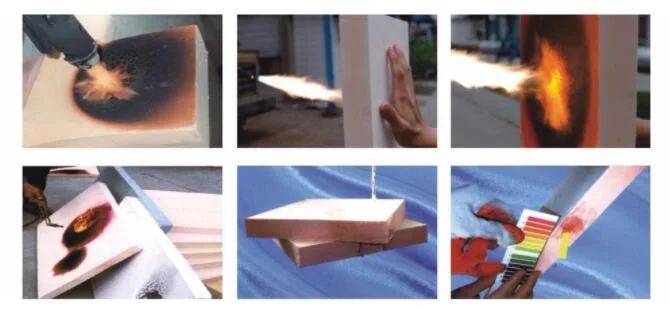

Characteristics of phenolic foam.

Thermal insulations: The thermal conductivity of phenolic foam is very low (0.021-0.028W/mk).

Fireproof: High Oxygen percent requirement. No dropping, no melting under high temperature but carbonized.

Less smoke emission and harmfulness: Low smoke emission under high temperature.

Chemical Resistances: Extreme anti-corrosion for acidity and alkalescency.

Durability: Available working temperature scale -140ºC to 160ºC. stable physical feature

Impervius: good closed cell structure, water absorption is low, performance of prevent the penetration of vapor is strong

Sound Absorption and noise reduction: has excellent sound absorption and noise reduction performance

Samll density, light weight: Phenlic insulation board density is below 100kg/m3, even as low as 50kg/m3

ASTM E-84, BS476, and UL181