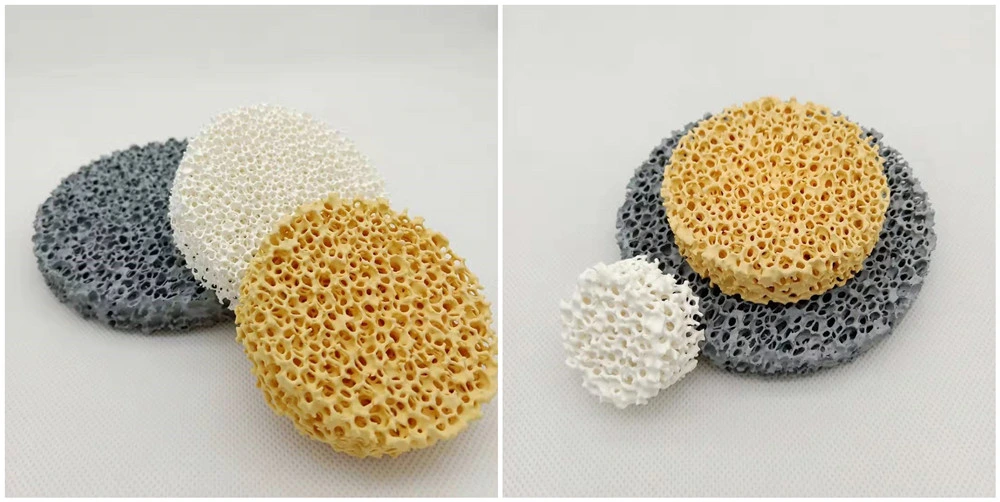

Alumina Sic Zirconia Ceramic Foam Filter for Ion Alloy Metal Casting

Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Material Specifications

| Material | Zro2 | SiC | Al2O3 |

| Color | Yellow | Grey | White |

| Pore density(ppi) | 8-60 | 8-60 | 8-60 |

| Porosity(%) | 80-90 | 80-90 | 80-90 |

| Operating temperature(ºC) | 1700 | 1500 | 1100 |

| Compression Strength(MPa) | 1.2 | 0.9 | 0.8 |

| Density(g/cm³) | 0.90-1.50 | 0.35-0.50 | 0.30-0.45 |

| Thermal Shock Resistance(1100-20ºC) | >6 times | >6 times | >6 times |

| Application | steel | iron | Non-Ferrous Alloy and Aluminium |

size and efficacy

Alumina Ceramic Foam Filters

| Dimensions(mm) | Pouring Rate(kg/s) | Filtration Capacity(ton) |

| 178*178*50 | 0.2-0.6 | 5 |

| 228*228*50 | 0.3-1.0 | 10 |

| 305*305*50 | 0.8-2.5 | 15 |

| 381*381*50 | 2.2-4.5 | 25 |

| 430*430*50 | 3.0-5.5 | 35 |

| 508*508*50 | 4.0-6.5 | 45 |

| 585*585*50 | 5.0-8.6 | 60 |

Zirconia Ceramic Foam Filters

| Dimensions(mm) | Pouring Rate(kg/s) | Filtration Capacity(kg) |

| 50*50*22 | 3-5 | 30 |

| 50*75*22 | 4-6 | 40 |

| 75*75*22 | 7-12 | 60 |

| 75*100*22 | 8-15 | 80 |

| 100*100*22 | 14-20 | 100 |

| D50*22 | 2-6 | 18 |

| D80*22 | 6-10 | 50 |

| D90*22 | 8-16 | 70 |

Silicon Carbide Ceramic Foam Filters

Dimensions(mm) | Pouring Rate(kg/s) | Filtration Capacity(ton) | ||

| Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

| 40*40*22 | 4 | 3 | 65 | 32 |

| 50*50*22 | 6 | 4 | 100 | 52 |

| 75*50*22 | 9 | 6 | 150 | 75 |

| 75*75*22 | 14 | 9 | 220 | 100 |

| 100*50*22 | 12 | 8 | 200 | 100 |

| 100*75*22 | 18 | 12 | 300 | 150 |

| 100*100*22 | 25 | 16 | 400 | 200 |

| 150*150*22 | 50 | 36 | 900 | 450 |

Features

Ceramic foam is a new industrial ceramic products with low bulk density (0.25 ~ 0.65) g/cm3, high porosity (60% ~ 90%), and three-dimensional reticulated structure. As ceramic foam has excellent properties such like: high temperature resistance, strong chemical corrosion resistance, and large surface area as a result of high porosity, it is widely used in molten metal filtration to remove undesirable nonmetallic inclusions in the melt.

Maximum Temperature

Up to 1000C for porous ceramic, limited only by sealants, gaskets and/or hardware

materials.

Corrosion Resistance

Porous ceramics are resistant to most acids, except for Hydrofluoric Acid and Phosphoric Acid. In alkaline solutions, porous ceramics are resistant up to pH9. It is also resistant to organic solvents. The sealants, gaskets and/or hardware materials used, may be the limiting factor in certain fluids.

Cleanability

Porous ceramic is cleanable by a variety of methods, depending on type of contaminant to be removed. Methods include spraying, brushing, backwashing, oven firing, dilute acid cleaning, solvent cleaning, steam cleaning and ultrasonic cleaning.

Applications

Porous ceramics are used for:

- Ceramic Vacuum Chucks

- Ceramic Filters

- Ceramic Diffusers

- Ceramic Air Bearings

- Ceramic Permeable Substrates

- Ceramic Dispersion Media

- Ceramic Ash Handling

- Ceramic Wicking Media

- Ceramic Fluidized Bed Plates

- Ceramic Specialty Spargers

- Ceramic Breathers - Vents

Similar products