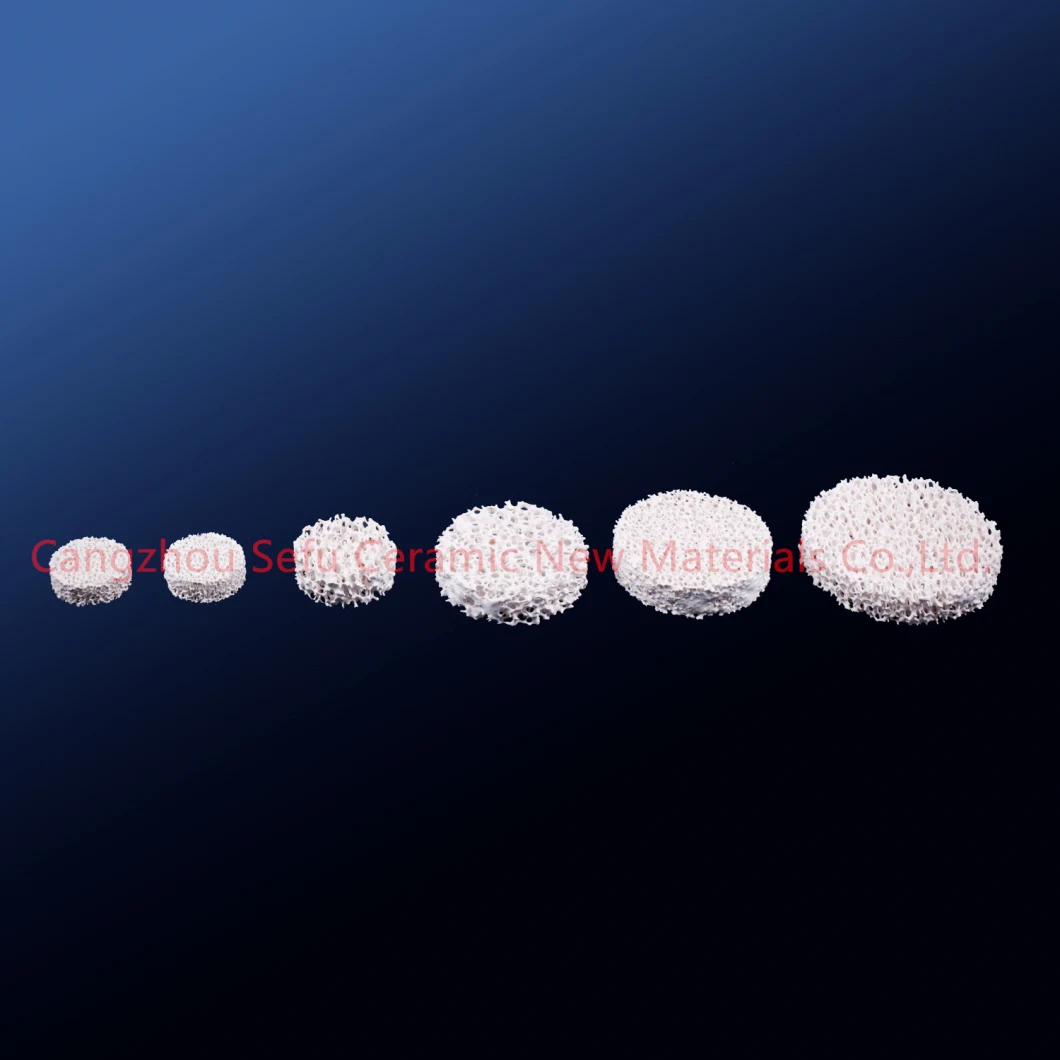

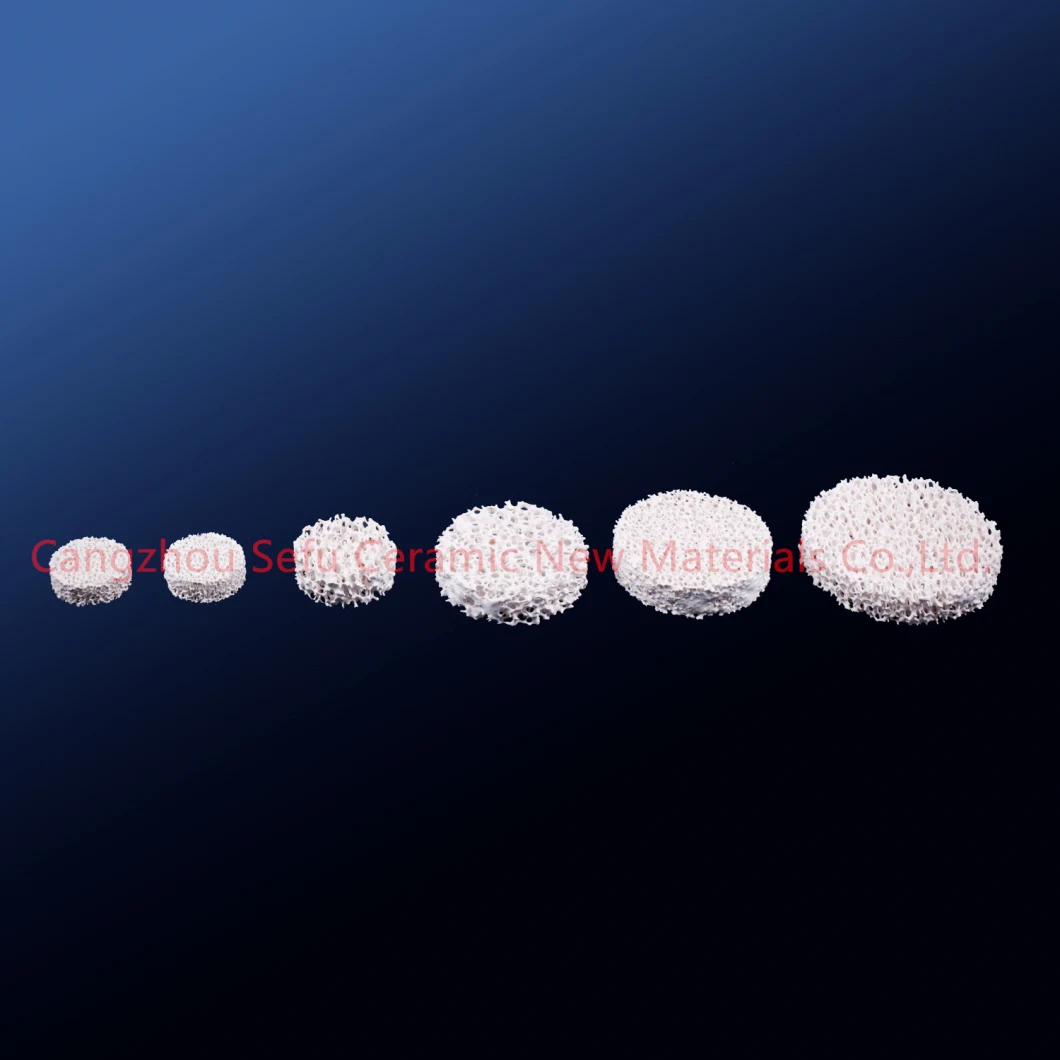

Alumina Ceramic foam filter

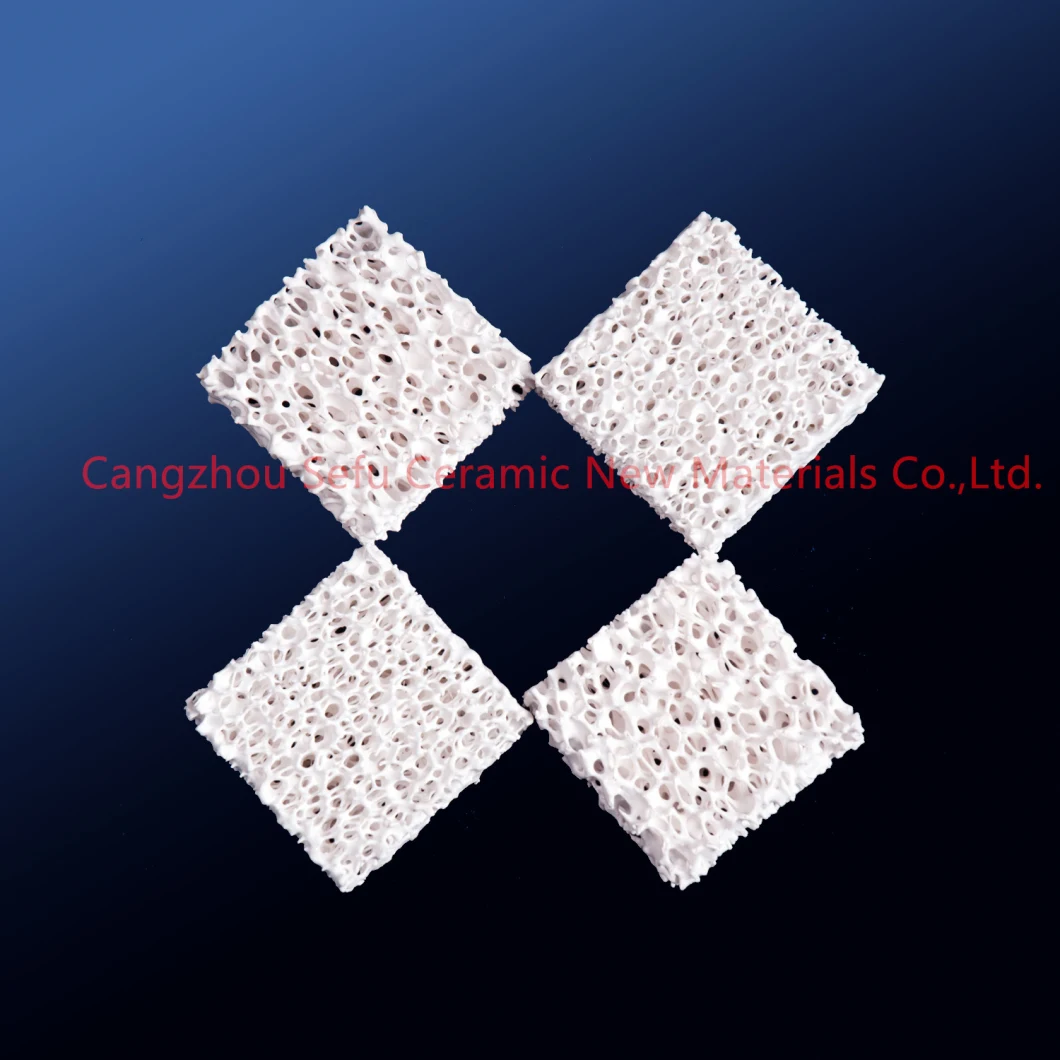

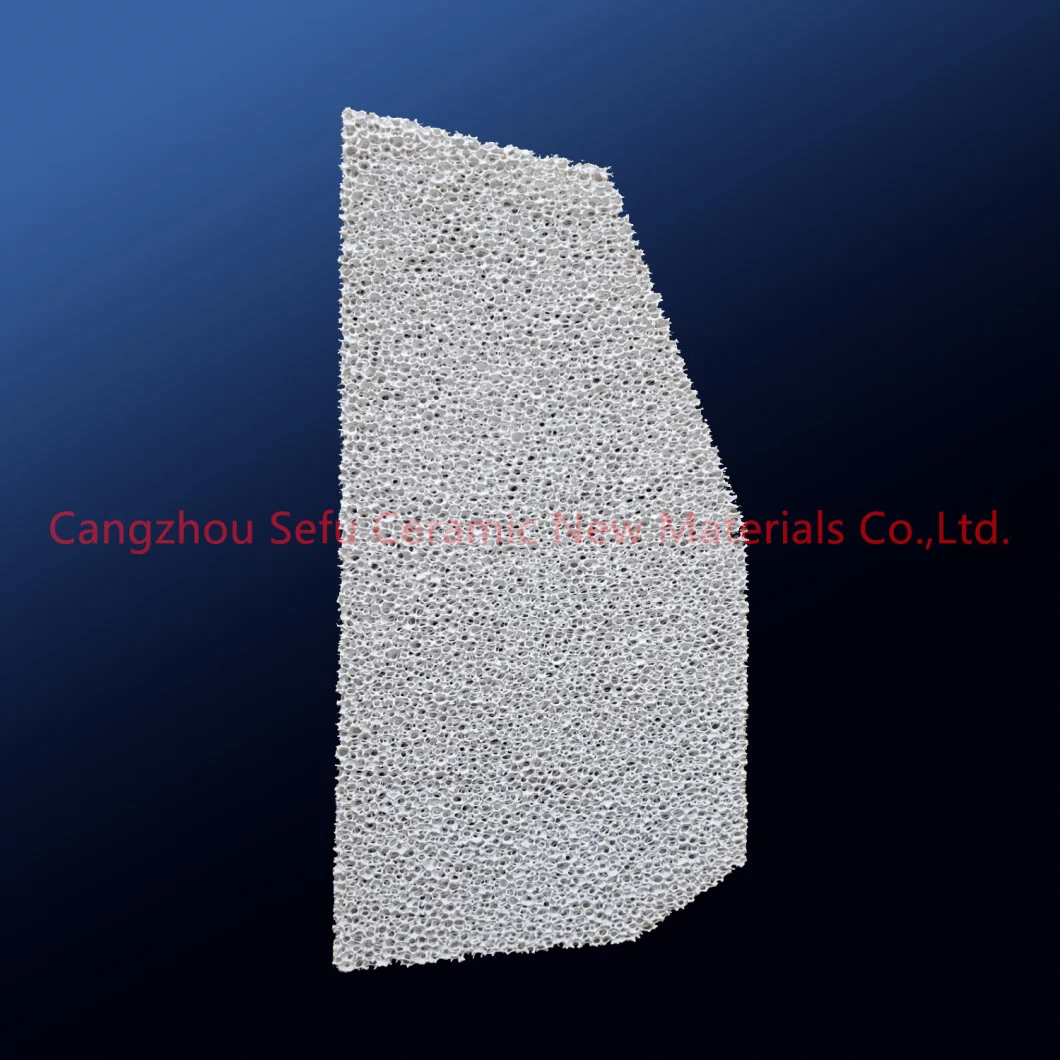

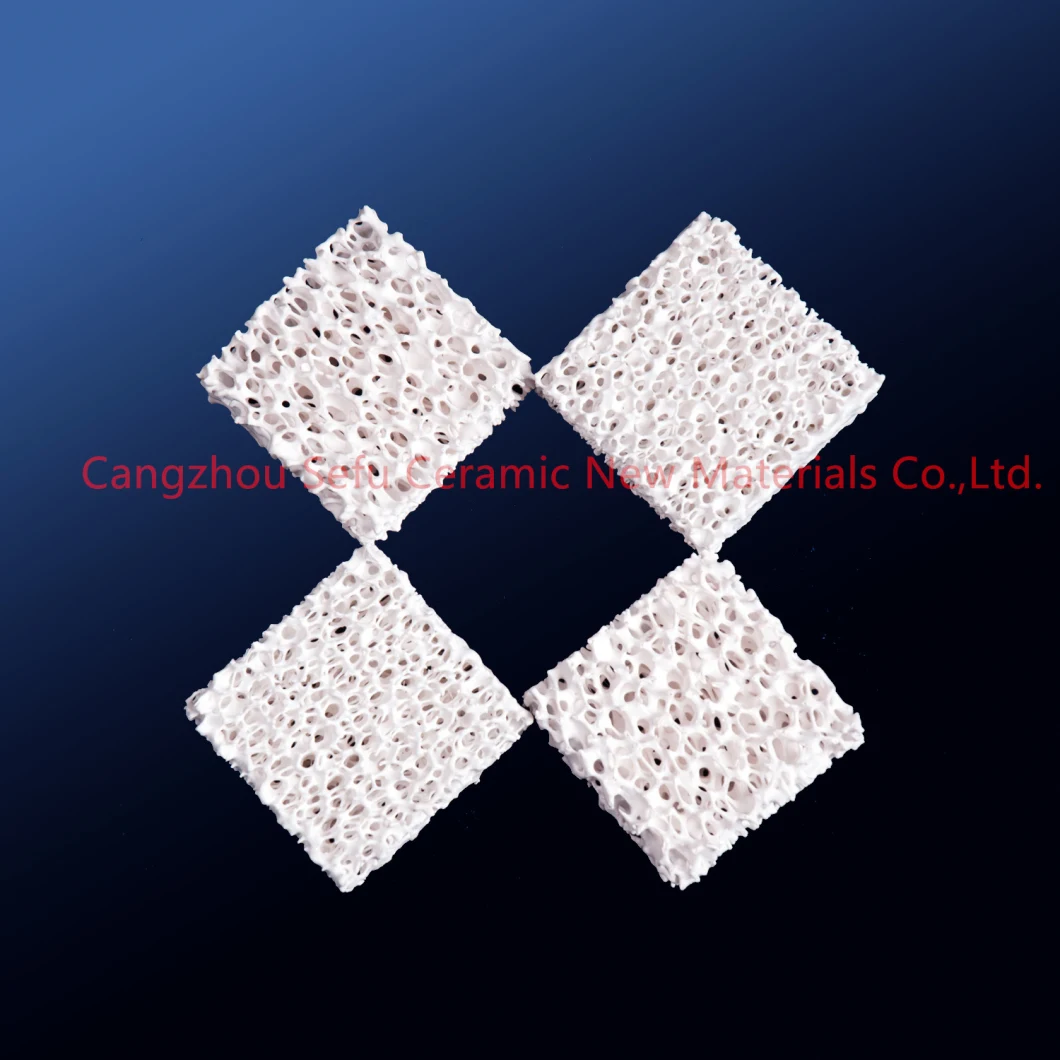

Alumina ceramic foam filter is a new type of low density, high porosity and with three dimensional network skeleton structure of the filter. And widely used in aluminum process industry for molten aluminum filtering, so as to improve aluminum quality.

Alumina ceramic foam filter can effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, to improve the quality of aluminum alloy and other non-ferrous alloy casting, all of which contribute to reduce casting cost, its maximum service temperature 1200°C.

Alumina ceramic foam filter has the advantages of high porosity, high mechanical strength, stable chemical property, strong corrosion-resistant, high adsorption rate, excellent filtering functions and thermal shock resistance. It is mainly used for purification process of aluminum, aluminum alloy, and other nonferrous alloy production, can also be used as gas-solid, liquid-solid separation medium, catalyst carrier, burner and sound-absorbing and environmental protection fields.

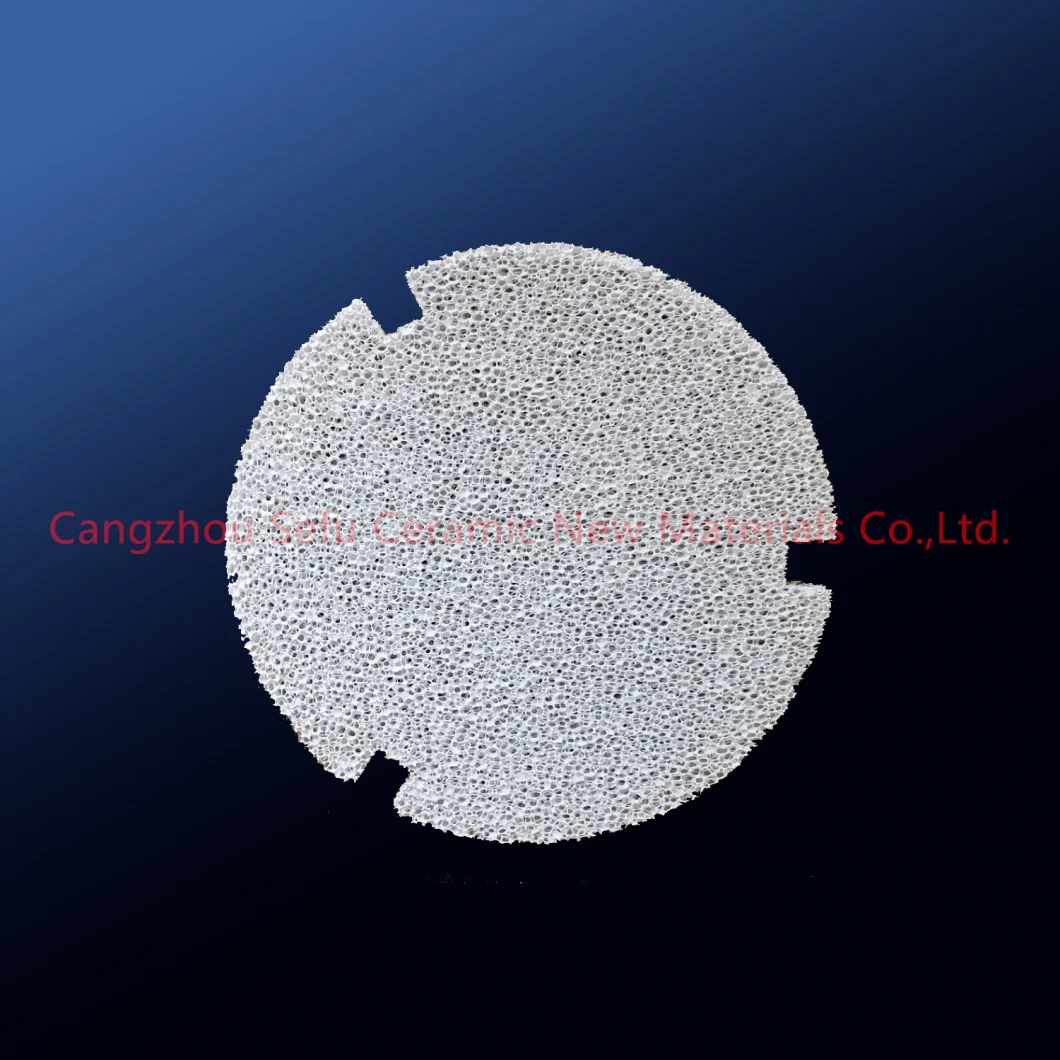

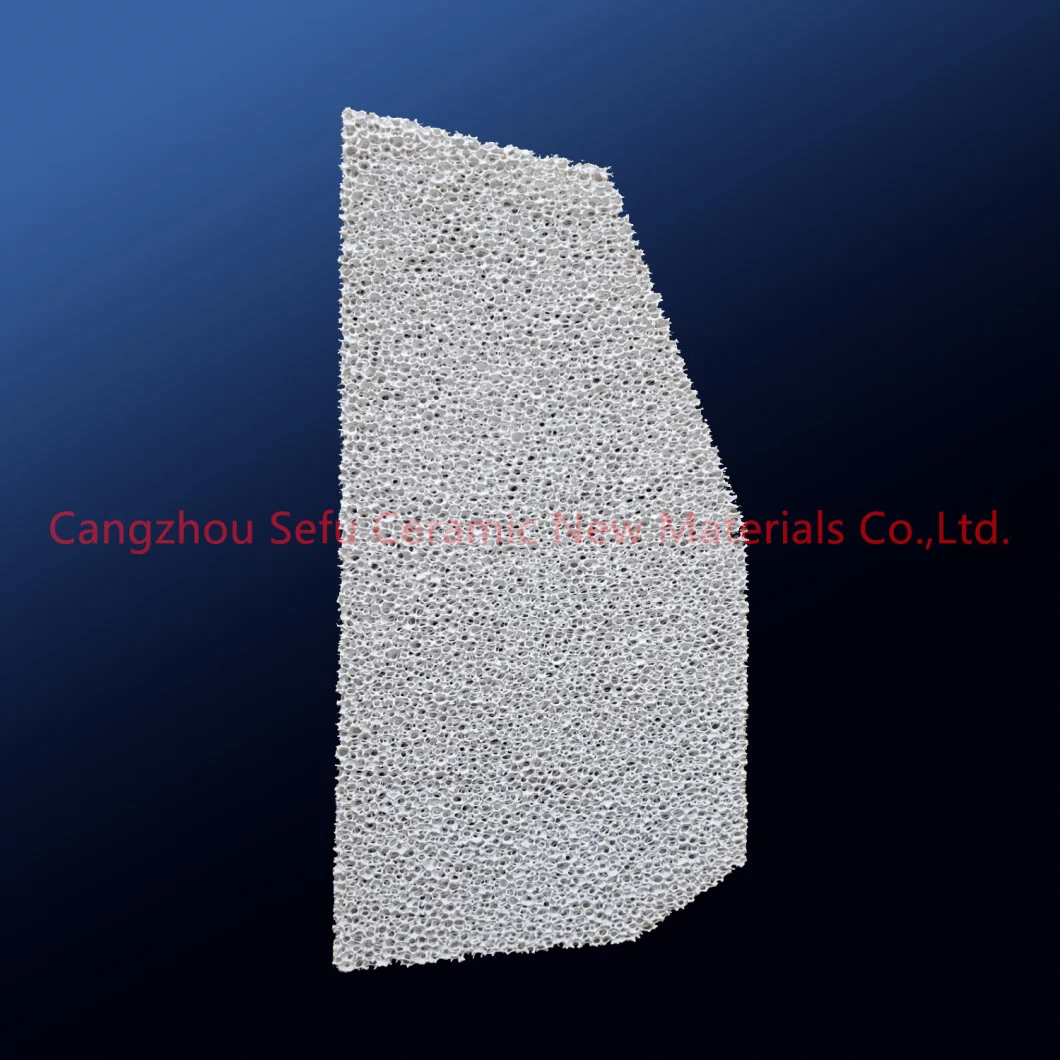

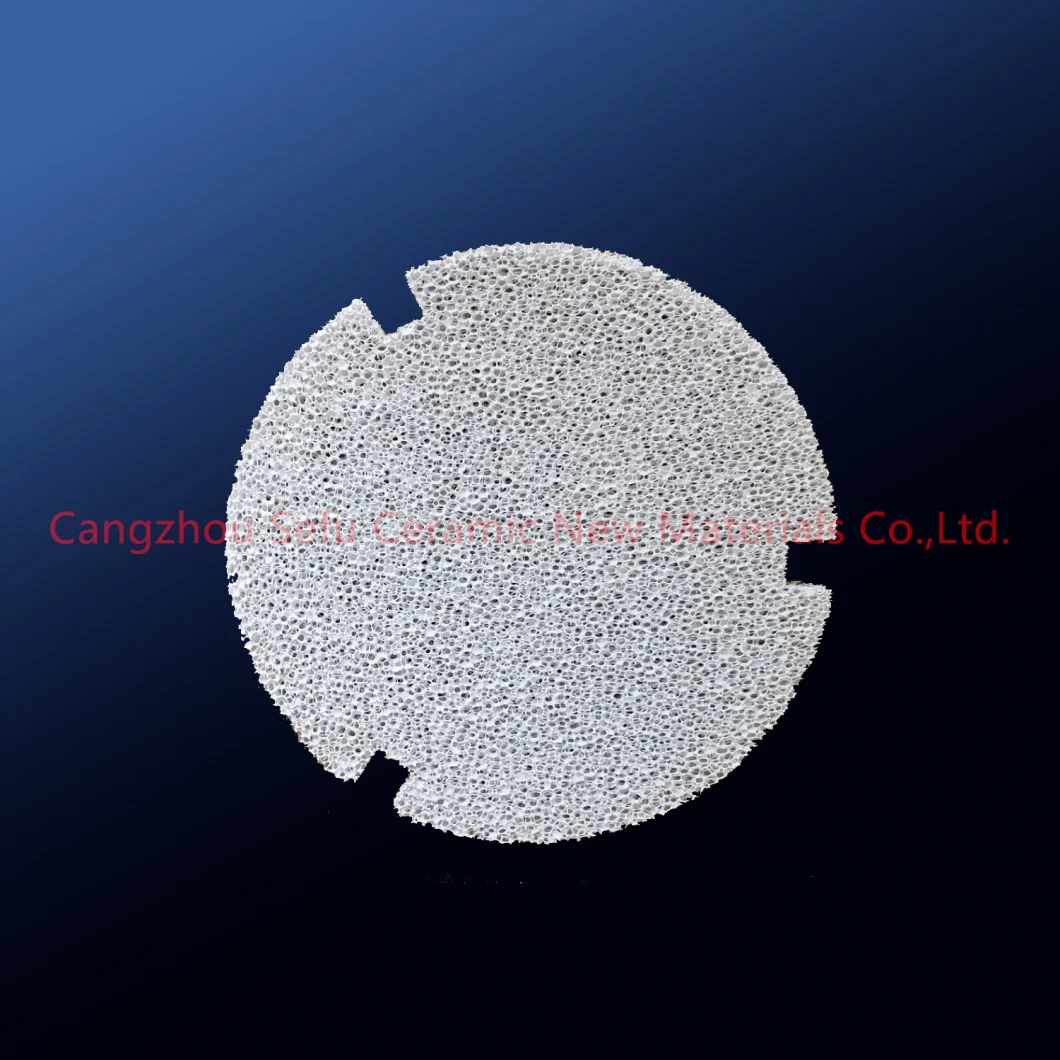

Alumina ceramic foam filter is equipped with a gasket on the edges; the gasket assures the proper and tight position of the filter within the filter box. There are different types of gasket available, e.g. ceramic fiber gasket etc., also can provide alumina ceramic foam filter without gasket. These types of filters have been favored by customers from Europe and the United States for years.

Alumina CFF Features

1. Superior dimensional tolerances.

2. Stable chemical property.

3. Excellent filtration efficiency.

4. Excellent mechanical strength.

5. Resistant to corrosion and thermal shock resistance.

6. Beveled edges and compressible gasket.

Product Application

Alumina ceramic foam filter is mainly applied to the aluminum and aluminum alloys fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting, also applied to other non-ferrous metal precision casting, gas-solid and liquid-solid separation medium, high temperature gas filter, chemical filling, sound absorbing material and catalysis carrier etc.

Alumina ceramic foam filter filter capacity

Filter capacity is derived from 20PPI filters

Alumina ceramic foam filter technical data

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide plastic bag, woven bag, carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceramic New Materials Co.,Ltd.

Alumina ceramic foam filter is a new type of low density, high porosity and with three dimensional network skeleton structure of the filter. And widely used in aluminum process industry for molten aluminum filtering, so as to improve aluminum quality.

Alumina ceramic foam filter can effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, to improve the quality of aluminum alloy and other non-ferrous alloy casting, all of which contribute to reduce casting cost, its maximum service temperature 1200°C.

Alumina ceramic foam filter has the advantages of high porosity, high mechanical strength, stable chemical property, strong corrosion-resistant, high adsorption rate, excellent filtering functions and thermal shock resistance. It is mainly used for purification process of aluminum, aluminum alloy, and other nonferrous alloy production, can also be used as gas-solid, liquid-solid separation medium, catalyst carrier, burner and sound-absorbing and environmental protection fields.

Alumina ceramic foam filter is equipped with a gasket on the edges; the gasket assures the proper and tight position of the filter within the filter box. There are different types of gasket available, e.g. ceramic fiber gasket etc., also can provide alumina ceramic foam filter without gasket. These types of filters have been favored by customers from Europe and the United States for years.

Alumina CFF Features

1. Superior dimensional tolerances.

2. Stable chemical property.

3. Excellent filtration efficiency.

4. Excellent mechanical strength.

5. Resistant to corrosion and thermal shock resistance.

6. Beveled edges and compressible gasket.

Product Application

Alumina ceramic foam filter is mainly applied to the aluminum and aluminum alloys fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting, also applied to other non-ferrous metal precision casting, gas-solid and liquid-solid separation medium, high temperature gas filter, chemical filling, sound absorbing material and catalysis carrier etc.

Alumina ceramic foam filter filter capacity

| Dimension inch | Dimension mm | Pore size ppi |

| 23*23*2 | 584*584*50 | 20/30/40/50 |

| 20*20*2 | 508*508*50 | 20/30/40/50 |

| 17*17*2 | 432*432*50 | 20/30/40/50 |

| 15*15*2 | 381*381*50 | 20/30/40/50 |

| 12*12*2 | 305*305*50 | 20/30/40/50 |

| 9*9*2 | 228*228*50 | 20/30/40/50 |

Filter capacity is derived from 20PPI filters

| Dimensions(inch) | Dimension( mm) | Flow Rate(kg Al/min) | Filter capacity(t Al) |

| 7' × 7' × 2' | 178 x 178 x 50 | 20-60 | 5 |

| 9' × 9' × 2' | 228 x 228 x 50 | 40-120 | 10 |

| 12' × 12' × 2' | 305 x 305 x 50 | 80-240 | 15 |

| 15' × 15' × 2' | 381 x 381 x 50 | 120-360 | 25 |

| 17' × 17' × 2' | 431 x 431 x 50 | 160-480 | 35 |

| 20' × 20' × 2' | 508 x 508 x 50 | 230-490 | 45 |

Alumina ceramic foam filter technical data

| Porosity(%) | 80~90% |

| Working Temperature | ≤1100°C |

| Bending Strength(Mpa) | 0.6 |

| Compression Strength(Mpa) | 0.8 |

| Thermal Shock Resistance | 1100°C---room temperature 6 times |

| Volume Density | 0.35-0.45 g/cm3 |

Detailed Images

Shipping

Lead time: 10-15days after signed the contract

Packing

- Inside packing: Filters are put in small box and Layered packaging. There is cardboard between each layer.

- Outside packing: Cartons&Pallets. Three layer corrugated cartons and export special pallets .

- The mark on cartons can be designed according to the customer's request.

FAQ

Q: Are you Factory?

A: Definitely, we are factory. Welcome to visit us!

Q: What Parameters should I provide to you for proper quotation?

A: Application, pore size, dimension, color, quantity, packing requirements, trade terms.

Q:How can you control your quality?

A:For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and we have the quality certificates with ISO9001.

Q: What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

Q: Do you provide Samples?

A: Yes, our factory provide samples for testing, pls send detail parameters to us. (if customized, with drawing is best) The samples will be charged or free according to the specific requirements.

Q: What's the Payment Terms?

A: We accept T/T, L/C, West Union, etc.

Q: How can I get samples?

A: We are honor to offer you the samples.

Q: What about your Packing?

A: We provide plastic bag, woven bag, carton box, pallet, etc. OEM packing available too.

Q: Do you have R&D services?

A: Yes, we have R&D department to assist you in new product development.

Q:Does your company accept customization?

A:We accept OEM service.

Q:Can we visit your company?

A:Yes, for sure, you are welcome to visit our company.

Contact us

Cangzhou Sefu Ceramic New Materials Co.,Ltd.